All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

-

Special effect paints

- Chameleon effect paints

- Paint with an opalescent pearlescent sheen

- Prismatic Paints

- Candy Paints

- The fluorescent paints

- Phosphorescent paints

- Fluorescent paints UV

- Crystal Pearlescent Clearcoat

- Marble and crystal paint

- Paints that react to temperature

- Paints that react to light

- Magnetic paint and rust color

- Chrome effects

-

Our paint ranges for bodywork

-

PAINT KIT FOR CAR BODYWORK

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

- Primers for car paints

- Epoxy-polyester paint for wheel rim

- Spraypaint bodywork

- Metallic effect paints for car bodywork

- Tuning paints with effects

- Pearlescent paints for bodywork

- Solvent-based 1K base coats for cars

- 2K paints for cars

- Vintage cars paints

- Rustproof car frame paints

- Car underbodies and pick-up trucks paints

- Car cylinder block paints

- Dashboard paints

- Car brake paints

- Plastic bumper paints

- Car wing mirror paints

-

CAR COLOUR CODE

-

PAINT KIT FOR MOTORCYCLE BODYWORK

-

Motorcycle and scooter paint code - Can or spray paint

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

- Motorcycle tuning paints

- Motorcycle paint primers

- Motorcycle spray paints

- Epoxy paints for motorcycle frames

- Epoxy paints for motorcycle rims

- Metallic motorcycle paints

- Pearly motorcycle paints

- Motorcycle clearcoats

- The paints for plastic of cross country motorcycle

- Jet ski hull paints

- Paints for Quad

-

Motorcycle and scooter paint code - Can or spray paint

- Scooter fairing paints

- Helmet paints

- Auxiliary products

- Bicycle paints - Stardust Bike

- RAL Paint - Pantone Code

-

PAINT KIT FOR CAR BODYWORK

- Finish paints and topcoats

-

Artistic and custom specialties

- EPOXY RESINS

- Gilding with a gold leaf

- Pinstriping paint and brushes

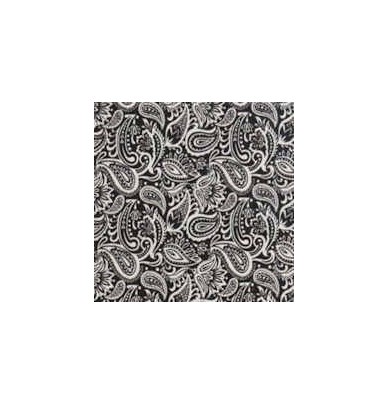

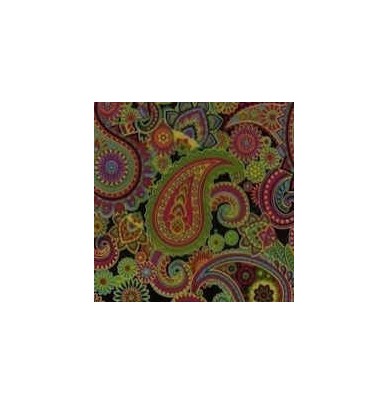

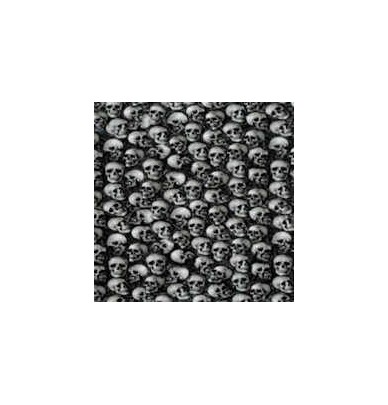

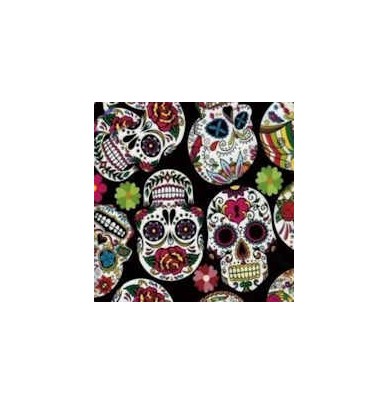

- Hydrographic Film

- Covering car and motorcycle

- Pearls and Flakes bodywork

- Painting over the body

- Paint for fishing decoys

- Paints for guitars

- HIKARI : paints for models and miniatures

- Acrylic 3D Printing Paint – Primers, Colors, and Clearcoat

-

Bodywork accessories and consumables

- HVLP Spray Guns for car and motorcycle paints

- Our ranges of airbrushes

- Compressed air connections

- BODYWORK ACCESSORIES

- Abrasives for bodywork

- Buffing and polishing of bodywork

- Protective Equipment for painters

- POSTERS

- Paint air filters

- sample supports for paint tests

- Infrared and ultraviolet drying lamps for paint

- Bodywork adhesives and paint

- Air compressors for painting

- Paints for airbrush

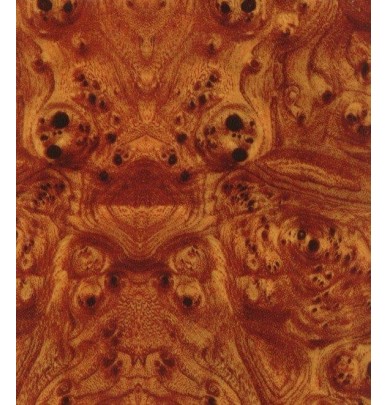

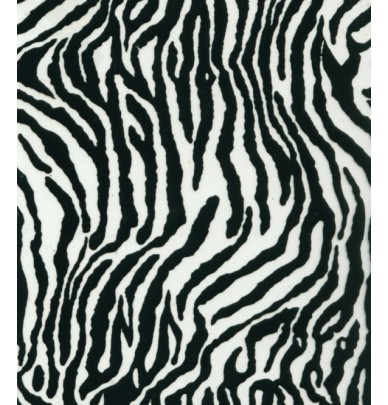

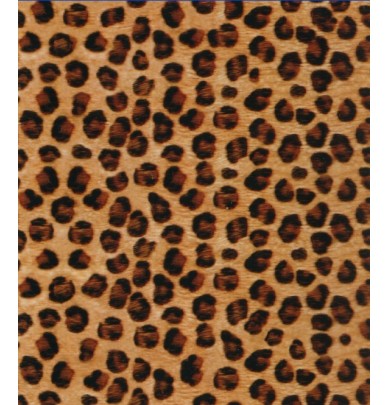

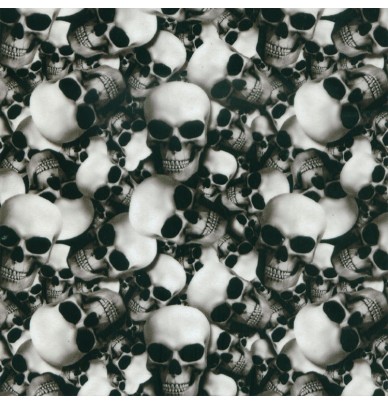

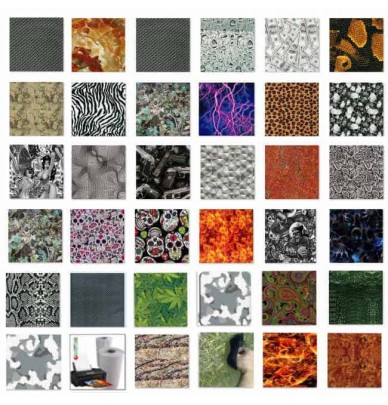

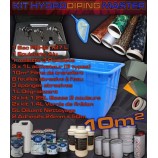

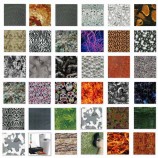

Hydrographic Transfer Film - 32 different patterns to choose.

New product

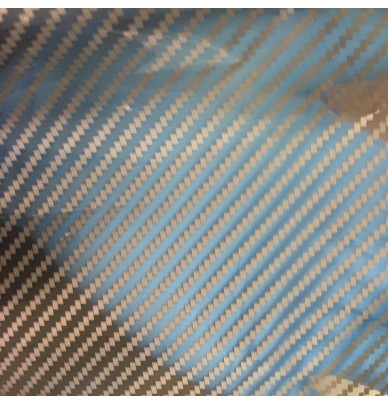

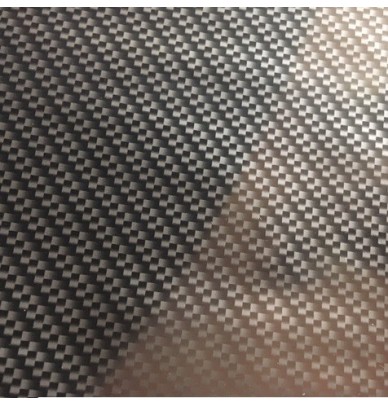

Film for water transfer and hydrodipping + 30 patterns

including a Holographic pattern.

hardening films available for cutting to m²

Select the pattern from the drop-down menu below:

Volume discounts

| Quantity | Price | You Save |

|---|---|---|

| 3 | 12.42£ | Up to 3.00£ |

| 5 | 11.42£ | Up to 10.00£ |

Water transfer printing, also known as Hydrographics or Immersion printing,

allows to apply, by dipping, onto the surface of an object, pre-printed patterns, provided as PVA inked film sheets.

The technique is simple and the results are quite impressive, in terms of quality and decorative imitation (wood, fibers, camouflage, skins...)

The process is well known to all, as it has been used for many years to create for example the wood paneling elements for dashboards.

Water Transfer Printing is applicable to all types of materials (from wood to glass), as long as the surface has been properly primed and/or prepared (cleaning, sanding, application of a primer )

Once the object has been decorated and top coated, it’s highly resistant and durable.

Please watch the videos on this page

PREPARATION

The first stage consists of degreasing, dusting, drying and sanding the object to create a good adherence.

In which cases should an adequate primer be applied to ensure perfect adherence ?

> On bare metals, plastic, glass and ceramics

A filler primer, that will need sanding, can be used on rough and irregular materials, such as wood.

Find all the primers in the section

PRIMERS

PRIMER

Depending on the transfer printing film used,

you can choose a primer or a paint (1K basecoat) which colour is close to the colour of the film for semi opaque films

or a black background for transparent films :

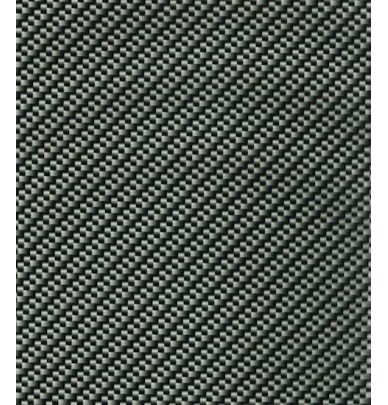

Examples : Black colour for carbon fiber (transparent film)

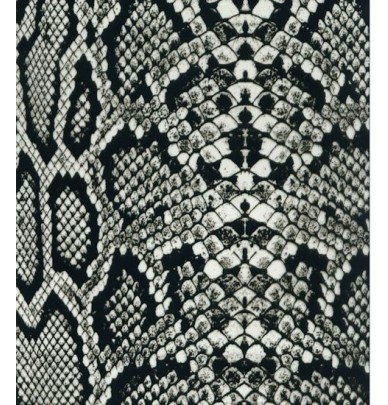

Choose a light color for the snake skin effect

The background must be sanded finely, be dry and free of any potential contamination (silicones, grease).

STEP BY STEP GUIDE :

HOW TO PLACE THE PRINTED FILM

Choose a dipping tank which is adapted to the size of the piece you want to soak in (deep enough, not too wide), and fill it with water at a constant temperature of 12 to 19°C.

Cut a piece of water transfer printing film, and apply masking adhesive tape all along these edges. The edges are taped to prevent any movements caused during the spraying of the activator chemical.

Carefully lay the film onto the water surface, facing downwards. Avoid air bubbles. Allow to stand for 1 to 2 minutes.

APPLY ACTIVATOR

Apply a quick coat of film activator with a sprayer or a spray gun, at a distance of 20 cm.

Leave on for 5 seconds before to lower the object to decorate into the tank.

(Please respect the safety instructions when applying the product)

DIPPING

Lower slowly the piece into the dipping tank, with an inclination of 30 to 45 °, and with a progressive forward movement.

Once the object is fully immersed, disperse what remains of the film on the surface of the water, before to remove the piece from the water

WASHING

Give the piece a long and thorough wash/rinse with hot water (around 50 to 60°C), to remove all ink residues that may be found on the surface of the piece

For very resistant materials such as metal, hot water may be used at temperatures up to 150°C.

DRYING AND TOPCOATING

Allow to dry thoroughly at room temperature or in an oven,

then a clear coat is applied to protect the design and give a beautiful glossy finish.

We recommend our automotive type UHS BS830 top coat, as it is among the strongest and brightest clear coats.

Storage :

The transfer film should be stored in a cool, dry place

Product catalogue

We can provide almost a thousand different various patterns. Ask anytime for our catalogue. Minimum Order : 100 or 250 sqm.

100m² = 500 € 250m²=1000 € (HT)

Additional Tips & Advice:

How to know the right side for film application? Simply run your wet finger across the surface, if it sticks, it's the right side facing down the water.

Do not put too much activator (1 pass is enough) and do not exceed the 15 seconds time of action.

After dipping the item in the water, hold it underwater for 5-10 seconds

Allow to dry for at least 1 minutes before to rinse:

Rinse thoroughly, until the oily layer disappears.

It is strongly advised to apply to our 2K Special Base for dipping all Cel-Dip substrates without sanding within 12 pm

Information for Carbon Films:

The 3 Hydrographic "Carbon" films have different pattern sizes:

GW12010 Opaque Carbon 1m: 5mm

GH112-1 Transparent Carbon 0.5m: 3mm

TSTR9031 Clear Carbon 1m: 4mm

Film patterns/Background colour Matching

Some films are opaque, others are transparent

Carbon GW12010: White background or Light background

Carbon GH112-1Trans: Black background

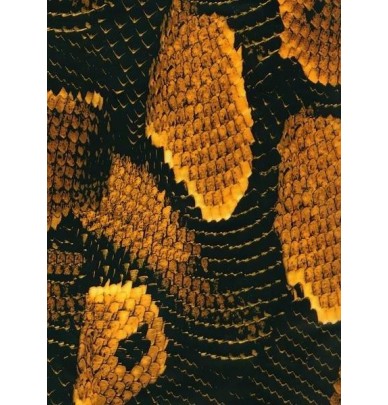

Snake GW2630: TAll lights Backgrounds, even pearls or metallics backgrouds

Snake Gold GM1208: White background or Light background

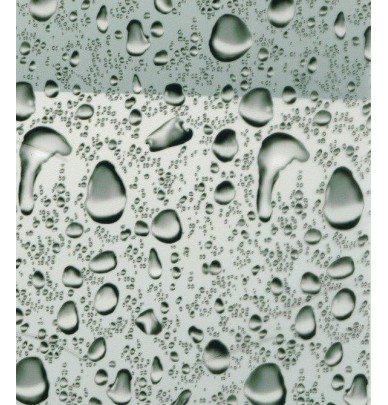

Bubbles GH158: All backgrounds except Black

Flame Skull GWR-006: White background

Wood GW2251: Brown background

Forest GW12526: White background

Dollar GH160 : White background

Marble GH006 : Light background

Mini Skull GWA147 : All lights Backgrounds, even pearls or metallics backgrouds

Puma GW12746 : White background or Light background

Zebra GW12484 : All backgrounds except Black

TSCF5084 LIGHTNINGS - Light background

TSCY197 ANTIC MAO - Light background

TSCY720 4DIMENSION - White background

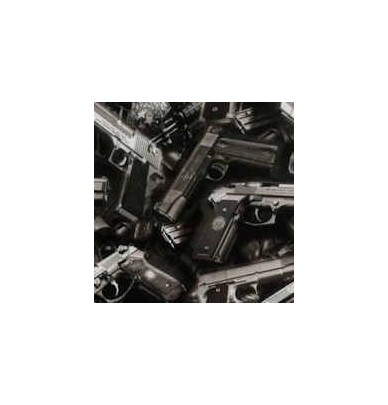

TSCY884 WEAPONS - White background

TSCY1012 3DIMENSION - White background

TSDY1971 RED MARBLE - Light background

TSHQ003 INDIAN GRAPHICS2 - Light background

TSHW9036 INDIAN GRAPHICS3 - Light background

TSHY678 INDIAN GRAPHICS4 - Light background

TSKH121 MINISKULLS 2 - Light background

TSKH3015 CALIFORNICATION - Light background

TSKK923 MEXICAN STYLE2 - White background

TSKK9088 TRUE FIRE - Light background

TSKR9009 CASINO 2 - Light background

TSKR9010 DARK SKULL - White background

TSMX433 GANJA 2 - Light background

TSPM061 DARK SNAKE - Light background

TSNY 3002 HOLOGRAPHIC LASER - Black Background Recommended

Accessories

15 other products in the same category

KIT HYDRODIPPING

125.90£

DIPPING TANK HOBBY BABY

2,604.00£

WE ALSO RECOMMEND YOU

Recently Viewed

- Special Effect Paints

- Chrome Effect

-

Car and motorcycle paint

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

.

.

.

-

MOTO COLOUR CODE

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

.

.

-

CAR COLOUR CODE

- Finish Paints and Topcoats

-

Specialties

-

Accessories and consumables

.

.

- AIRBRUSH PAINT

- COLORCHART