All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

High resistance polyurethane paints

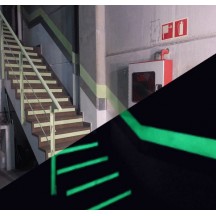

It’s the most resistant and also the most used professional version among phosphorescent paints for safety. The phosphorescent polyurethane paint can be considered as a polyurethane topcoat because it’s bright and colourless. They are professional technical coatings that provide great hardness and extremely tight seal, for both indoor and outdoo...

Read more-

Phosphorescent Polyurethane clearcoat PHU2K 1.33L

In Stock 32.40£Two-component photoluminescent polyurethane varnish Several versions to select from the packaging menu (flexible or hydro (water) versions are special versions) -

Phosphorescent paint for roads and bike paths

In Stock 91.80£Paint for exterior roadsCycle or pedestrian pathsSolvent-based acrylicsSecond layer of the Photoluminescent system for road PH1041To be applied over white road undercoat ST1041Complete kit packaging kit 1,33 kg kit 6.65 kg kit 26.6 kg (base and pigment) -

White or colored road sign paint

In Stock 22.68£Exterior paint for exterior roadsPaints for bicycle and pedestrian pathsAcrylic solvent basedUndercoat for photoluminescent paint PH1041 Packaging kit 1 kg / 5 kg Several colors to choose from -

-

Full Mask Reusable Cartridge

In Stock 37.80£Protect your health with a GERSON mask Product in stock, usually ships within 24 hours -

Portable Mini Torch Type UV Lamp

In Stock 4.54£Ultra violet flashlightProduct in StockDelivered without batteries48 hour delivery -