All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

Solvent-based 1K base coats for cars

Among other types of car paints Stardust offers a complete range of solvent-based car paints, including 1K basecoats.

What is a 1K basecoat ?

First of all, it is a one-component paint : no hardener is needed*.

It is a thin paint, drying at room temperature.

It is not an overcoat : the paint must be quickly varnished, with a topcoat. The latter ...

Read more-

Urethan paint – Base coat auto paint

In Stock 32.00£1K automotive Basecoat 9 colours in stockDelivery time 48hrs. -

RAL paint spray

In Stock 26.76£Spray paint all colors RAL to choose 2 formats :- Basecoat 1C- Shiny 2C Order shipped the same day if placed before 11am -

-

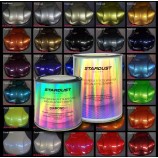

RAL or PANTONE® Tints in 1K Basecoat version

In Stock 26.34£PACKAGING for our 1K Basecoat with RAL or PANTONE® colour matching :- 250ml Ready to use- 500ml Ready to use- 1L Kit : 0.5L Pure tint + 0.5L Thinner- 2L Kit : 1L Pure tint + 1L Thinner- 10L Kit : 5L Pure tint + 5L Thinner- 400ml Aerosol- Pack of 3 Aerosols, 400ml -

GULFORANGE and GULFBLUE paint

In Stock 13.08£The two famous colors, Blue and Orange of the Gulf Racing team for you, in cans or in sprays Delivery 48h Offers from 125 ml to 5 L -

1K transparent binder

In Stock 34.80£3 packagings available : 500mL / 1L / 5L 3 types : HS or MS or Crystal -

-

-

Texture additive for paints

In Stock 21.60£Propyltex® structured effect for paints 4 grain sizes for texture effectsmicronized grain effect Supplied in 125g or 1Kg jar Compatible in all paints Not dangerous48h delivery - in stock -

OPAQUE AIRBRUSH SOLVENT-BASED PAINTS -125ml

In Stock 11.73£ 13.80£Reduced price!GRAPHIC Range for airbrush 54 different opaque shades in stock To choose -

Semi-transparent AIRBRUSH PAINTS

In Stock 11.73£ 13.80£Reduced price!GRAPHIC Range Semi transparent serie 11 references in stock -

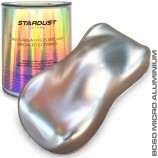

METALLIC PAINT Spray 400ml + GOLDEN GOLD-BRONZE-COPPER-ALUMINUM

In Stock 22.57£Range of metallic paints in 400ml Spraycan Shipping in Europe only -

METALLIC PAINTS 500ml / 1L + GOLDEN GOLD-BRONZE-COPPER-ALUMINUM

In Stock 41.32£A range of 19 metallic paints for automotive and bikes 1L Sizes Stock: Available Delivery: 48h -

DIAMOND EFFECT PAINT 250ml - 500ml

In Stock 32.32£Glitter Pearl Diamond paint in 1/4 L size, pre-diluted Application on white or black background Please refer to the colour chart in PDF -

DIAMOND SPRAY 400ml

In Stock 26.90£Glitter Pearl Diamond paint Application on white or black background Please refer to the colour chart in PDF -

Audi car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£All original Audi coloursProfessional car paint (solvent base)In cans or aerosol sprays among these packagings- 400 ml aerosol spray paint- Set of 3 aerosol sprays- 250 ml- 500 ml- KIT 1L - KIT 2L Audi code to be provided when ordering -

BMW car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£BMW paint : all colour codes in solvent basein packaging : - 250 ml Ready to use- 500 ml Ready to use- KIT 1L : 0.5L colour + 0.5L thinner- KIT 2L : 1L colour + 1L thinner- KIT 10L : 5L colour + 5L thinner- 400 ml aerosol spray- Set of 3 aerosol sprays 400 ml48h delivery -

Citroën car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Citroen paint : all colour codes in solvent basein packaging : - 250 ml Ready to use- 500 ml Ready to use- KIT 1L : 0.5L colour + 0.5L thinner- KIT 2L : 1L colour + 1L thinner- KIT 10L : 5L colour + 5L thinner- 400 ml aerosol spray- Set of 3 aerosol sprays 400 ml -

FIAT car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Fiat paint – 1K basecoatin cans or aerosol spraysWith StardustColors, you can choose from a range of 250 ml to 10L cans or aerosol sprays, and benefit from 48 hour delivery. -

FORD car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£All original Ford coloursProfessional car paint (solvent base)In cans or in aerosol sprays among the following packaging : - 400 ml aerosol spray paint - Set of 3 aerosol sprays - 250 ml - 500 ml - KIT 1L - KIT 2L Ford code to be provided after order -

MERCEDES car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Mercedes paint – 1K basecoat in 250 ml to 5L cans or aerosol sprays - 250 ml - 500 ml- KIT 1L : 0.5L pure + 0.5L thinner- KIT 2L : 1L pure + 1L thinner- KIT 10L : 5L pure + 5L thinner- 400 ml aerosol spray- 3 aerosol sprays 400 ml -

OPEL car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Opel paint : All colours in cans or aerosol sprays 250 ml diluted 500 ml diluted KIT 1L : 0.5L pure + 0.5L thinner KIT 2L : 1L pure + 1L thinner Aerosol spray 400 ml Set of 3 aerosol sprays 400 ml -

PEUGEOT car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£PEUGEOT paint – 1K basecoat in 250 ml to 5L cans or 400 ml aerosol spray - 250 ml Ready to use- 500 ml Ready to use- KIT 1L : 0.5L tint + 0.5L thinner- KIT 2L : 1L tint + 1L thinner- KIT 10L: 5L tint + 5L thinner- 400 ml aerosol spray- Set of 3 aerosol sprays 400 ml DELIVERY 48h -

PORSCHE car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£PORSCHE 1K basecoat (two-coat paint) Choose your packaging from :- 250 ml Ready to use- 500 ml Ready to use- KIT 1L : 0.5L colour + 0.5L thinner- KIT 2L : 1L colour + 1L thinner- KIT 10L : 5L colour + 5L thinner- 400 ml aerosol spray- Set of 3 aerosol spays 400 ml -

RENAULT car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Packaging to choose from :- 250 ml Pre-diluted- 500 ml Pre-diluted- KIT 1L : 0.5L pure + 0.5L diluent- KIT 2L : 1L pure + 1L thinner- KIT 10L : 5L pure + 5L thinner- 400 ml aerosol spray- Set of 3 aerosol sprays 400 ml Need advice ? Write to us at info@stardustcolors.com ! -

TOYOTA car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£All paint colours of Toyota vehicles of your choice : - 250 ml Ready to use - 500 ml Ready to use - KIT 1L: 0.5L colour + 0.5L thinner - KIT 2L: 1L colour + 1L thinner - KIT 10L: 5L colour + 5L thinner - 400 ml aerosol spray - Set of 3 aerosol sprays 400 ml -

ASTON MARTIN car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Choose your ASTON MARTIN solvent-based car paint in spray or can1/ Select the format of your choice from the drop-down menu2/ Choose your delivery method at home or at a "relay point"3/ And send us your ASTON MARTIN color code by emailAvailable:Aerosol 400mlLot of 3 Aerosol250ml500mlSET 1L2L KIT -

VOLKSWAGEN car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Here are our different formats for a Volkswagen car paint code : 400 ml aerosol spray Set of 3 aerosol sprays 400 ml 250 ml (can) 500 ml (can) KIT 1L (can) KIT 2L (can) Colour reference to be sent by email after ordering -

KIA car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Order your KIA car paint code with 48 hour delivery Choose your packaging, then order. The colour code you want must be communicated to us after the order, by email - 400 ml aerosol spray - Set of 3 aerosol sprays - 250 ml - 500 ml - KIT 1L - KIT 2L -

Alfa Romeo car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£On this page order the ALFA ROMEO car paint codeAccording to the original factory paint in spray or potOffers with 48-72h deliveryAerosol 400 mlkit of 3 Aerosols 400ml250ml pre-diluted500ml pre-dilutedKIT 1L 0.5L pure + 0.5Ldiluent)KIT 2L (1L pure + 1L diluent) -

Cadillac car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Get your Cadillac car paint codeMade according to the factory colorPaint shipped the same day for an order before 12:00 p.mChoice of:Spray 400mlSet of 3 Spray250ml diluted500ml dilutedKit 1L (paint and thinner)Kit 2L -

Chevrolet car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£CHEVROLET car paint codeSelect the packaging:Aerosol 400mlPack of 3 Aerosol250ml500mlKit 1LKit 2LSend us your color code after ordering -

Dacia car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£DACIA car paint code all original shades in solvent-based varnish baseShade to be specified by email after orderingIn pot or spray can among these packaging400ml spray paintSet of 3 spray cans250ml500ml1L kit2L kit -

Ferrari car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£We carry out FERRARI car painting and deliver quicklyAt home / At work / or at a relay point6 formats available, in aerosols or pots:Aerosol 400mlSet of 3 Aerosols250ml500mlKit 1LKit 2L -

Hyundai car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£All Hyundai car paint codes according to the original shades in 1C varnish baseFast delivery - code to send us by email after orderingAvailable formats:400ml aerosolSet of 3 aerosols250ml500ml1L kit2L kit -

Jaguar car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Formulation of a JAGUAR* car paint code on request, depending on the packaging:400ml aerosolSet of 3 400ml aerosols250ml (pot)500ml (pot)1L KIT (pots)2L KIT (pots)*Code to be sent by email after ordering -

Lamborghini car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£We manufacture your Lamborghini car paint code from all original formulasSame day shipping for orders before 12 noon Formats to choose from400ml spray paintSet of 3 spray cans250ml500mlKIT 1LKIT 2L -

Land Rover car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£We prepare your LAND ROVER car paint the same day.Several versions to choose fromAerosol 400mlLot of 3 Aerosol250ml500mlKIT 1LKIT 2LWe deliver quickly to the office, home, or relay point -

Lexus car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Get your Lexus car paint code faithfully made according to the factory colorPaint shipped the same day for an order validated before 12 noon,Delivery in 48-72 hours. Choice of:Spray 400mlSet of 3 Spray250ml diluted500ml dilutedKIT 1L* (paint and thinner)KIT 2L -

Mazda car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Choose your Mazda car paint codeSpray 400mlSet of 3 Sprays250ml pre-diluted500ml pre-dilutedKIT 1L (500ml pure + 500ml thinner)KIT 2L (1L pure + 500ml thinner)Delivery in 48-72 hours at your home or at a relay point -

Mini car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Order the MINI COOPER car paint code in a pot or aerosol:Spray 400mlSet of 3 Sprays250ml pre-diluted500ml pre-dilutedKit 1L (500ml pure + 500ml thinner)Kit 2L (1L pure + 500ml thinner)Delivery 48-72 hours to your home or to a relay point -

Nissan car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£All NISSAN car paint codesIn spray:Spray 400mlSet of 3 SpraysOr in can :250ml diluted500ml dilutedKit 1L (500ml pure + 500ml thinner)Kit 2L (1L pure + 500ml thinner)Delivered in 48-72 hours relay or at home / at work -

Seat car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Your SEAT car paint code to order and receive in 48-72 hours here:Versions available in spray paintSpray 400mlSet of 3 SpraysOr for paint gun250ml diluted500ml dilutedKit 1L (500ml pure + 500ml thinner)Kit 2L (1L pure + 500ml thinner) -

Skoda car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Need a touch-up with a SKODA car paint code?Benefit from 48-72h delivery to your home or collection point.Formats to choose from:Aerosol 400mlSet of 3 Aerosol250ml500mlKit 1LKit 2LSKODA color code to be sent by email after ordering -

Volvo car paint code - Car colour code in 1K solvent-based basecoat

In Stock 27.00£Order any VOLVO car paint code with the factory shade,in professional solvent-based body paint versionSpray paint / pot paint:400ml spray paintSet of 3 spray cans250ml500ml1L kit2L kitDelivered in 48-72 hours to your home or to a relay point