All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

Spray paint for 3D printing – Primer, paint and clearcoat

To decorate and personalize 3D resin or plastic prints, it is possible to apply paints with an airbrush, a pneumatic gun, and when you do not have a compressor or tools, with aerosols.

Spray paints are solvent-based products packaged in aerosols pressurized with a propellant gas (75% of the volume).

Spraying paints allows for optimal application,...

Read more-

Spray Primers for 3D Printing – Aerosol Primers and Fillers

In Stock 16.20£Spray primer and undercoat for 3D printing Several types in the STARDUST 3D Range 1K Filling primer gray SPR-P440 2K Filling primer 5 colors SPR-P410 Primer for plastics SPR-P230 Primer for resins REPAINT SPR-P540 Suitable for Figurines, miniature figurines, cosplay, jewelry, mechanical parts, articulated toys.. -

-

PLASTIC PRIMER / MONO-COMPONENT ADHESION PROMOTER P230

In Stock 21.60£Paint for Plastic - All plastic adhesion primer A special liquid and transparent product to promote adhesion over various plastic surfaces.Product available. -

Spray paint for bikes - 63 colors Graphic 400 ml - STARDUST BIKE

In Stock 23.76£Opaque colors 63 shades available 400 ml spray 1K basecoat type. In stock -

RAL paint spray

In Stock 26.76£Spray paint all colors RAL to choose 2 formats :- Basecoat 1C- Shiny 2C Order shipped the same day if placed before 11am -

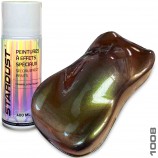

Colorshift effect chameleon paint in spraycans 400ml

In Stock 35.02£CHAMELEON SPRAY PAINT 17 colours Standard available Products available immediately. Delivery in 48h-72h No air shipping! -

DIAMOND SPRAY 400ml

In Stock 26.90£Glitter Pearl Diamond paint Application on white or black background Please refer to the colour chart in PDF -

METALLIC PAINT Spray 400ml + GOLDEN GOLD-BRONZE-COPPER-ALUMINUM

In Stock 22.57£Range of metallic paints in 400ml Spraycan Shipping in Europe only -

Spray clearcoat 2C – UHS professionnal bicomponent topcoat

In Stock 26.70£Ultra High Solid Clearcoat for professionnal Fuel resistant 2K clearcoat -

Bi-component matte aerosol spray topcoat - 2 matte or satin effects

In Stock 27.00£Professional polyurethane matte topcoatVery high resistance290ml format, hardener includedSingle use aerosol -

-

Stardust Bike spray topcoat for bikes, gloss and matte, high resistance

In Stock 27.00£High resistance two-component spray can for bikes Stardust Bike range topcoats to choose from : BIKE-830 UHS TOPCOAT BIKE-821 SATIN TOPCOAT BIKE-822 EXTRA MATT TOPCOAT BIKE-FLEX FLEXIBLE TOPCOAT BIKE-8010 1K TOPCOAT BIKE-P510 CARBON TOPCOAT BIKE-UV ANTI-UV TOPCOAT BIKE-MAT 1K MATT TOPCOAT