All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

-

Special effect paints

- Chameleon effect paints

- Paint with an opalescent pearlescent sheen

- Prismatic Paints

- Candy Paints

- The fluorescent paints

- Phosphorescent paints

- Fluorescent paints UV

- Crystal Pearlescent Clearcoat

- Marble and crystal paint

- Paints that react to temperature

- Paints that react to light

- Magnetic paint and rust color

- Chrome effects

-

Our paint ranges for bodywork

-

PAINT KIT FOR CAR BODYWORK

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

- Primers for car paints

- Epoxy-polyester paint for wheel rim

- Spraypaint bodywork

- Metallic effect paints for car bodywork

- Tuning paints with effects

- Pearlescent paints for bodywork

- Solvent-based 1K base coats for cars

- 2K paints for cars

- Vintage cars paints

- Rustproof car frame paints

- Car underbodies and pick-up trucks paints

- Car cylinder block paints

- Dashboard paints

- Car brake paints

- Plastic bumper paints

- Car wing mirror paints

-

CAR COLOUR CODE

-

PAINT KIT FOR MOTORCYCLE BODYWORK

-

Motorcycle and scooter paint code - Can or spray paint

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

- Motorcycle tuning paints

- Motorcycle paint primers

- Motorcycle spray paints

- Epoxy paints for motorcycle frames

- Epoxy paints for motorcycle rims

- Metallic motorcycle paints

- Pearly motorcycle paints

- Motorcycle clearcoats

- The paints for plastic of cross country motorcycle

- Jet ski hull paints

- Paints for Quad

-

Motorcycle and scooter paint code - Can or spray paint

- Scooter fairing paints

- Helmet paints

- Auxiliary products

- Bicycle paints - Stardust Bike

- RAL Paint - Pantone Code

-

PAINT KIT FOR CAR BODYWORK

- Finish paints and topcoats

-

Artistic and custom specialties

- EPOXY RESINS

- Gilding with a gold leaf

- Pinstriping paint and brushes

- Hydrographic Film

- Covering car and motorcycle

- Pearls and Flakes bodywork

- Painting over the body

- Paint for fishing decoys

- Paints for guitars

- HIKARI : paints for models and miniatures

- Acrylic 3D Printing Paint – Primers, Colors, and Clearcoat

-

Bodywork accessories and consumables

- HVLP Spray Guns for car and motorcycle paints

- Our ranges of airbrushes

- Compressed air connections

- BODYWORK ACCESSORIES

- Abrasives for bodywork

- Buffing and polishing of bodywork

- Protective Equipment for painters

- POSTERS

- Paint air filters

- sample supports for paint tests

- Infrared and ultraviolet drying lamps for paint

- Bodywork adhesives and paint

- Air compressors for painting

- Paints for airbrush

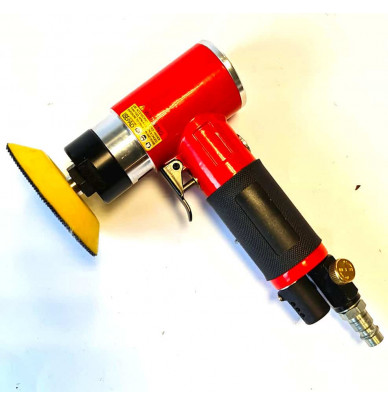

A3301 Pneumatic 50mm Eccentric Mini Sander with 50 Mini Discs

New product

Pneumatic Tool, Quality Grade B, Japanese Standard

High Quality

3mm Orbital Rotation*

50mm Backing Plate

2 options available (Micro Sanding or Micro Repair)

1/ Micro Sanding Offer

The Grade B Mini Sander ensures high power and rotational speeds up to 15,000 revolutions per minute. The orbital mini sander can accommodate 50mm or 75mm backing plates. Grade B Mini Sanders are professional-grade pneumatic tools. Amongst various quality grades from D to A, this 50mm mini sander matches the quality standards of the Japanese market, which has requirements similar to the European market. Another model of the mini sander is available at a budget-friendly price (see below).

What differentiates a budget sander from a professional sander ?

The Grade B professional mini sander delivers a sanding power far superior to consumer-grade sanders. With an equal compressed air source, a second-tier sander stops rotating when too much pressure is applied, while the professional sander maintains high performance even under increased force.

Usage :

The pneumatic mini sander is convenient to use and easy to handle. It features a speed control dial and a trigger to initiate rotation. A minimum of a fifty-litre compressor is required.

Delivery :

Supplied with a 50mm VELCRO self-adhesive pad, a pneumatic connector, and 50 micro sanding discs of 50mm from coarsest to finest (Grades: 10x320, 10x800, 10x1500, 10x2000, 10x3000).

We offer optional mini sanding pads of 50mm or 75mm, with a soft grade (red) and a standard firm grade (yellow) here.

We also offer 50mm water sanding discs with various grain finenesses (P320, P800, P1500, P2000, P3000) here.

What's the difference between a mini-sander and a mini-polisher ?

For a mini-sander, the rotational speed is much higher (12,000-15,000 rpm*) compared to a mini-polisher, which caps at 2,500 revolutions per minute.

*revolutions per minute

Orbital / Excentric :

This refers to an orbital sander type with an orbit of t5.

Unlike concentric rotation, the orbital system rotates the pad on an axis that itself revolves in a circle measured in mm. This ensures no marks are left on the surface; the sanding pattern is not concentric (revolving around a fixed axis). Even if one stops moving the active sander, it won't create a hole or a sanding mark because the disc forms a variable ellipse.

2 / Micro Repair Kit Offer

Mini Sander + Mini Polisher System : Rapid Defect Repair

Our rapid bodywork defect repair kit includes this mini sander in a micro sanding + micro polishing system. This system allows professionals to address minor imperfections ranging from a few millimetres to several centimetres in under five minutes, facilitating a swift delivery to the client:

The rapid repair system ensures impeccable finishing quality, correcting flaws without the need for paint touch-ups, clear coat applications, or the full process of using a paint booth, application, and drying.

Process Overview :

Step 1 : Using the 50mm mini sander, wet sand with 1500 / 2000 / 3000 grit. Clean the disc with your finger.

Step 2 : Check the defect using a blue pad. If the flaw persists, repeat the sanding.

Step 3 : Polish using the micro polisher, 75mm sheep's wool pad, and Mirka Polarshine polishing compound. Clean with a microfibre cloth.

Step 4 : Polish using the micro polisher, 75mm black foam pad, and a suitable polishing compound.

Accessories

24 other products in the same category

Recently Viewed

- Special Effect Paints

- Chrome Effect

-

Car and motorcycle paint

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

.

.

.

-

MOTO COLOUR CODE

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

.

.

-

CAR COLOUR CODE

- Finish Paints and Topcoats

-

Specialties

-

Accessories and consumables

.

.

- AIRBRUSH PAINT

- COLORCHART