All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

-

Special effect paints

- Chameleon effect paints

- Paint with an opalescent pearlescent sheen

- Prismatic Paints

- Candy Paints

- The fluorescent paints

- Phosphorescent paints

- Fluorescent paints UV

- Crystal Pearlescent Clearcoat

- Marble and crystal paint

- Paints that react to temperature

- Paints that react to light

- Magnetic paint and rust color

- Chrome effects

-

Our paint ranges for bodywork

-

PAINT KIT FOR CAR BODYWORK

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

- Primers for car paints

- Epoxy-polyester paint for wheel rim

- Spraypaint bodywork

- Metallic effect paints for car bodywork

- Tuning paints with effects

- Pearlescent paints for bodywork

- Solvent-based 1K base coats for cars

- 2K paints for cars

- Vintage cars paints

- Rustproof car frame paints

- Car underbodies and pick-up trucks paints

- Car cylinder block paints

- Dashboard paints

- Car brake paints

- Plastic bumper paints

- Car wing mirror paints

-

CAR COLOUR CODE

-

PAINT KIT FOR MOTORCYCLE BODYWORK

-

Motorcycle and scooter paint code - Can or spray paint

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

- Motorcycle tuning paints

- Motorcycle paint primers

- Motorcycle spray paints

- Epoxy paints for motorcycle frames

- Epoxy paints for motorcycle rims

- Metallic motorcycle paints

- Pearly motorcycle paints

- Motorcycle clearcoats

- The paints for plastic of cross country motorcycle

- Jet ski hull paints

- Paints for Quad

-

Motorcycle and scooter paint code - Can or spray paint

- Scooter fairing paints

- Helmet paints

- Auxiliary products

- Bicycle paints - Stardust Bike

- RAL Paint - Pantone Code

-

PAINT KIT FOR CAR BODYWORK

- Finish paints and topcoats

-

Artistic and custom specialties

- EPOXY RESINS

- Gilding with a gold leaf

- Pinstriping paint and brushes

- Hydrographic Film

- Covering car and motorcycle

- Pearls and Flakes bodywork

- Painting over the body

- Paint for fishing decoys

- Paints for guitars

- HIKARI : paints for models and miniatures

- Acrylic 3D Printing Paint – Primers, Colors, and Clearcoat

-

Bodywork accessories and consumables

- HVLP Spray Guns for car and motorcycle paints

- Our ranges of airbrushes

- Compressed air connections

- BODYWORK ACCESSORIES

- Abrasives for bodywork

- Buffing and polishing of bodywork

- Protective Equipment for painters

- POSTERS

- Paint air filters

- sample supports for paint tests

- Infrared and ultraviolet drying lamps for paint

- Bodywork adhesives and paint

- Air compressors for painting

- Paints for airbrush

Stardust Bike spray topcoat for bikes, gloss and matte, high resistance

New product

High resistance two-component spray can for bikes

Stardust Bike range topcoats to choose from :

BIKE-830 UHS TOPCOAT

BIKE-821 SATIN TOPCOAT

BIKE-822 EXTRA MATT TOPCOAT

BIKE-FLEX FLEXIBLE TOPCOAT

BIKE-8010 1K TOPCOAT

BIKE-P510 CARBON TOPCOAT

BIKE-UV ANTI-UV TOPCOAT

BIKE-MAT 1K MATT TOPCOAT

A bike topcoat is the final, clear coat.

Applied over the base paint, this topcoat can be gloss, satin or matte, and has a dual function :

protection of the paint system* and the frame, against abrasion, shocks, oxidation, UV, and also the aesthetic aspect of glossiness*.

We invite you to read the definition of "paint system" at the bottom of the page to understand the best way to achieve a resistant and long-lasting paint

►TUTORIAL: HOW TO PAINT A BIKE ?

The STARDUST® BIKE spray topcoat range

We offer several choices of bike spray topcoats according to the requirements of each, whether it is for road bikes, cross-country bikes or all-terrain bikes.

The 2K STARDUST BIKES topcoats are two-component* solvent-based spray topcoats, they include a hardener, and are single-use, they allow a thickness and a resistance much higher than the classic 1K topcoats. They are the same as those used in the car / motorcycle world.

A STARDUST® 2K Spray topcoat for bikes cures by chemical polymerization, while a 1K topcoat simply cures by drying and evaporating with air.

|

References StardustBike |

Designation |

type |

|

|

UHS |

UHS high brilliance bike topcoat |

2K |

High solids topcoat, glossiness over 95°, durable glossiness over 10 years. |

|

FLEX |

Anti-shock topcoat Flex |

2K |

UHS gloss flexible anti-chipping topcoat, excellent gloss and resistance. Recommended for cross-country bikes and extreme conditions, including stone and gravel projections. Drying time : through-drying : 12-24h |

|

ST822 |

Matte topcoat |

2K |

The first matte spray topcoat. |

|

Carbon |

Topcoat for carbon |

2K |

Direct adhesion gloss topcoat special raw carbon. Drying time : through-drying : 12h |

|

UV |

Anti-UV topcoat |

2K |

Gloss topcoat specially reinforced with anti UV, to protect fragile colors. It absorbs and blocks a large part of the UV rays. Drying time : through-drying : 12-24h |

|

1K |

Gloss topcoat 8010 |

1K |

Fast monocomponent topcoat. Excellent coverage and thickness. High brilliance, ultra fast drying, direct adhesion on metals except chrome. Reusable. Drying time : through-drying : 1-2h |

|

MAT 1K |

Matt Topcoat |

1K |

Matt Varnish 680050. Quick-drying varnish |

Aerosol sprays delivered with round nozzles

Coverage of aerosol can topcoat for a bike

It takes 1 to 2 spray cans to paint a bike frame.

Varnishing with only one aerosol can is possible, as long as you avoid losses during application on the tubular surfaces of the frame.

The liquid content (topcoat + hardener) of a 400 ml aerosol can is 150 ml. The remaining amount is gas.

The mini pot varnish kit with hardener and thinner, for application with a paint gun, is available.

Application of spray can topcoat on a bike

A topcoat is applied either on

-

unsanded paint freshly applied (for less than 30 minutes) or

-

dry and sanded with P500. If you wish to sand finer, the guarantee of good performance is no longer assured.

A topcoat is always applied in 2 coats, with a certain time interval to allow the first coat to "set" and avoid drips.

The time interval is 7 to 10 minutes ideally, depending on the temperature.

It is not recommended to varnish more than 2 coats during the varnishing process, as this will lower the level of brilliance, rather than increase it.

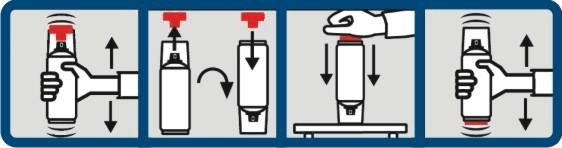

A Stardust Bike spray can topcoat has a button at its base that must be pressed to impact the aerosol spray : press the red button several times until it is fully depressed, then shake the aerosol spray for 30 seconds. Preferably wait 2 minutes before using.

Use the topcoat within 30 minutes after pressing the button.

Impact resistance and risk of delamination

Stardust Bike 2K topcoats are resistant to everything: water, detergents, chemicals and fuels, scratches and rubbing, they do not yellow.

To resist scratches, a bike topcoat must be either very hard or flexible.

With constant exposure to stone chips, a hard topcoat can break and crack.

To remedy this, Stardust Bike FLEX UHS topcoats contain plasticising and elasticating additives, just like truck bumpers, to absorb impact without breaking.

Delaminations :

No topcoat comes off spontaneously or after a shock. If a delamination occurs, the cause is a bad application :

Either the support is not suitable for this topcoat (plastic, carbon, aluminum...)

Or the topcoat has been applied over a paint or primer not properly sanded.

If the topcoat comes off with the paint, then the adhesion defect is between the paint and the base.

Tip for varnishing technique with an aerosol spray

Apply a gloss coat in a back and forth motion, keeping the spray can 15cm away from the bike frame. Always keep the spray can moving. The key to successful polishing is to apply the maximum amount : too little polish will result in a lackluster or "orange peel" surface, and too much polish will result in drips.

We recommend using our aerosol spray handle available at the bottom of the page.

Do not varnish in wet weather, otherwise the brilliance will be lost during the drying process.

To avoid dust and dirt during drying, choose a day without wind, and wet the floor and the surrounding walls.

Varnish preferably at a temperature of 15 to 25°C.

* Definition of « paint system »

This refers to a process composed of steps and techniques to make up the coating (on a metal, aluminum, carbon bike frame), serving both as a protection of the frame (oxidation) and as an aesthetic and decorative finish.

Exemple : primer + paint + topcoat

We call a « 1K system » all systems involving a base paint + a topcoat.

In contrast, a bicomponent (2K) paint is both the paint and the topcoat, in a single step.

1K systems are used in the world of bike painting as well as in the automotive industry.

In a 1K system :

The base paint is monocomponent (1K)

The topcoat is bicomponent (2K)

The same paints are used and the resistance of the system is ensured by the finishing topcoat.

How do I remove drips from a topcoat ?

If you overloaded or varnished at a too low temperature, the topcoat "slips" and forms drips.

To repair these defects, the drips must be allowed to harden for several days. Then, you can sand with water and a P500 sand paper, using a gentle rotary motion, on the top of the drip. It is important to use a mini wedge, and for this you can use a flat eraser.

Then, varnish the area, or varnish the entire frame, previously cleaned with P500.

Safety :

Flammable and harmful products. Be sure to read the safety data sheets before use.

Always work with sufficient air extraction / circulation and with a paint mask.

Accessories

30 other products in the same category

WE ALSO RECOMMEND YOU

Recently Viewed

- Special Effect Paints

- Chrome Effect

-

Car and motorcycle paint

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

.

.

.

-

MOTO COLOUR CODE

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

.

.

-

CAR COLOUR CODE

- Finish Paints and Topcoats

-

Specialties

-

Accessories and consumables

.

.

- AIRBRUSH PAINT

- COLORCHART