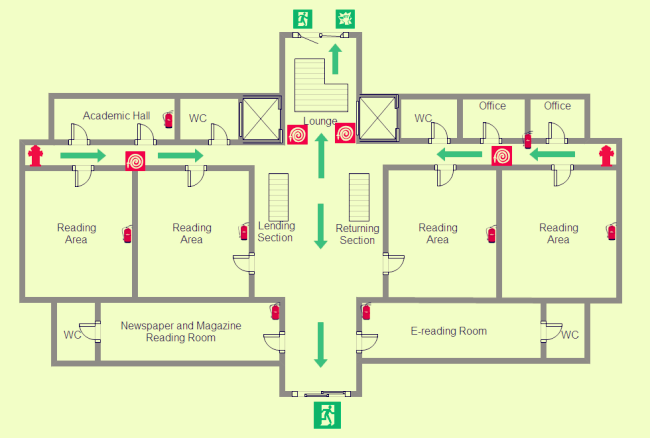

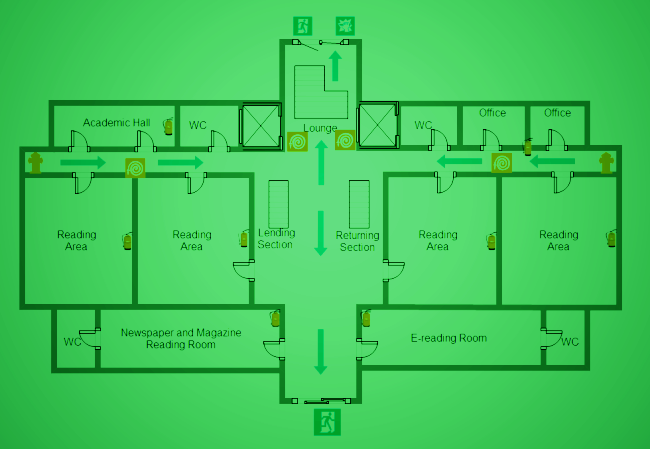

In establishments open to the public, such as gymnasiums, museums, hotels, ships but also in certain factories, it is required to install a Photoluminescent PVC evacuation plan in order to guide the occupants towards the exits in case of emergency and especially in the event of lighting cuts.

In establishments open to the public, such as gymnasiums, museums, hotels, ships but also in certain factories, it is required to install a Photoluminescent PVC evacuation plan in order to guide the occupants towards the exits in case of emergency and especially in the event of lighting cuts.

It can also be safety instructions for the use of fire-fighting equipment, the use of a machine or emergency contact.

A photoluminescent security plan stores ambient light energy, whether natural or electrical, and permanently releases it in the form of photoluminescence : that is to say, it glows in the dark.

European standards govern phosphorescence levels : luminance (intensity of phosphorescence) and remanence (duration of phosphorescence) must be of a class C level. These performance indications must appear on the photoluminescent safety plan.

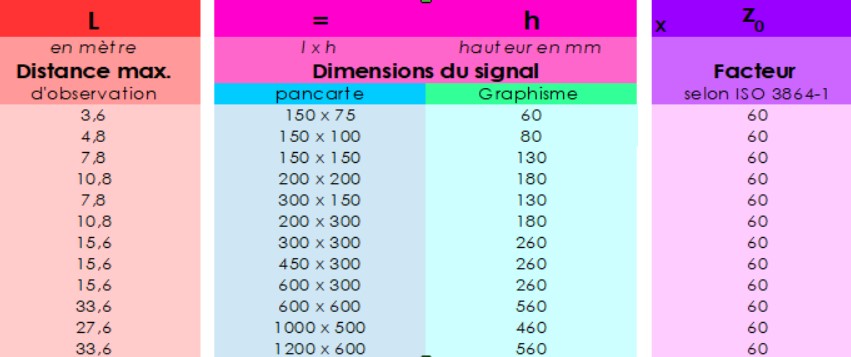

General sizes

The most frequently printed size is A4. It is possible to print larger plans, depending on the observation distance, and also depending on the complexity and importance of the evacuation plan.

It is possible to order free sizes and formats.

Contact ARCO IRIS SAS at info@phosphorescent.fr for prices and to obtain the printing of a photoluminescent safety and evacuation plan.

The different mediums

The different mediums

In general, evacuation plans are always made on PVC panels. It is a light and economical material, easy to print, and suitable for all interior areas. It is rare to place a security plan in an outdoor area, however, when it is necessary to have an evacuation plan resistant to heat or weather, then more materials such as aluminum are used. or stainless steel as a support.

Printing modes

Screen printing is the method that has been used the most since photoluminescent planes have existed. It is particularly economical and practical when printing a large number of identical plans. It turns out to be less interesting when it comes to printing one, or even 2 or 3 plans, because you have to make a “screen” for each drawing, and each colour.

Today we use more the laser printing method, which allows four-color prints to be made which is quite economical.

The fixing method

The safety boards measure approximately 1-1.5mm thick and are easy to attach to walls or doors, with double-sided adhesive tape. It is also possible to screw them, or even to install them with frames.

The costs

The costs

For a photoluminescent PVC evacuation plan, the price varies according to the size, quantity and type of materials.

Initially, as for all printing works, If a single photoluminescent plan is printed, the work of setting up and adjustments will be equivalent to that necessary for the printing of 50 photoluminescent plans.

There is therefore a sliding scale of tariffs.

In addition to the price, which logically varies according to the size of the plan, there are also different costs for the material of the support :

In addition to the price, which logically varies according to the size of the plan, there are also different costs for the material of the support :

Rigid PVC plans are by far the most economical.

The price range then goes up with the aluminum tops, and goes up again with the stainless steel plates.

Leave a Reply