All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

Chrome paint - professional spraygun version

Liquid paint with mirror chrome effect, to be applied with a spray gun or airbrush.

Chrome Spray Paint intended for the bodywork, high temperature and UV resistant.

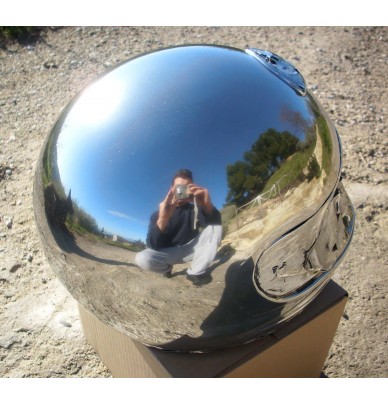

Mirror effect 75-80% (topcoated) to 90% (unvarnished)

Works on all glossy and hardened 2C coatings

CHROME SPRAY PAINT WITH MIRROR EFFECT

Our new 2020 version

Choosing Chrome spray paint is cost effective (covers 5 sqm per Litre), practical, non-toxic and it produces a splendid chrome finish that imitates the closest the look of chrome plating

INSTRUCTIONS

Apply only with a spraygun or with an airbrush only (small nozzle size). Chrome paint has the advantage to require no special equipment, a simple spraygun and an air compressor are enough. Anyone can successfully use Chrome spray paint, on condition of respecting closely the instructions.

Here is the summary of the method of application:

- glossy black undercoat: 24h of drying

- Chrome spray paint, applied in very thin layers

- Optional step, to be done after 48h: Topcoating

About the critical step the BASECOAT

It’s the most delicate and most important condition for the quality of the chrome paint: a black paint must be applied over, glossy and lacquered and as hard as possible. For this you can use :

- our polyurethane black lacquer BESANATO (for all supports)

- our ST8900X basecoat / clearcoat to obtain the best results (maximum hardness, accelerated drying)

Note : the quality of the mirror finish will depend of its glossiness, its dry time and the hardness of the basecoat.

A long drying will allow a complete hardening and the evaporation of all solvents.

TOPCOAT:

We recommend our ST8900X basecoat / clearcoat, which can be used as an undercoat, and also as a glossy and resistant topcoat.

Optional and to determine according to use. Any type of topcoat is fine. Precautions to be taken with solvent-based clearcoats. Topcoating is not mandatory and intended only for pieces that are subject to abrasion and to outdoors conditions such as rain. For objects meant indoors, non subject to repeated friction and contacts, we don’t recommend to topcoat: without clear-coat, the Chrome spray paint aspect is at its best.

DESTINATION

Cars, bikes, rims, headlights, design, sculpture, pipes... Different material types can be painted : metal, aluminium, plastics, wood, polycarbonate, as long as the material has been prepared prior to applying the basecoat.

CHARACTERISTICS

Solvent- based paint ready to use.

In all cases: Good resistance to high temperature and UV. No yellowing of the paint.

Without topcoat: You will achieve a 100% chrome effect, no peeling, but sensitivity to abrasion. Recommended for suspended objects/sculptures or kept in closed places

With topcoat: The mirror-like effect will be a bit dull. Perfect resistance to bad weather conditions, heat, UV, abrasion. Not guaranteed to adhere: avoid shocks with sharp objects, or removal of stickers

INDUSTRIAL VERSION :

StardustColors proposes an industrial chrome paint system, that provides excellent adhesion and accelerated implementation through baking.

There are countless application possibilities: Equipment, mobile, bottles, decoration, etc.

Find out more about the system here

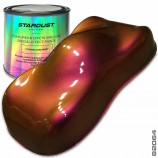

COLOUR

Chrome can display gorgeous "candy" colours. It's easily obtained by adding our Candy inks in the clearcoat (see our section Candy concentrate or topcoats

SPECIFICATION SHEET AND INSTRUCTIONS:

TOOLS: HVLP or conventional spraygun, airbrush (nozzle 0.5 to 1.0 mm)

COVERAGE:1L / >5 sqm

APPLICATION:

UNDERCOAT: We recommend the special undercoat ST8900 basecoat / clearcoat to obtain the best chrome effect and to shorten drying times considerably. With any other gloss black polyurethane paint, allow at least 7 days of drying and hardening. Do not sand or use a degreaser. Simply dust with a dry and soft cloth.

CHROME PAINT: Shake well before use. Spray very thin passes with a spraygun with small nozzle size (0.5~1.0mm) and a low pressure (2 bars), reducing the paint flow at the maximum (press slightly on the trigger) and by letting the air escape, until you reach maximum chrome effect. Allow a few seconds between each pass to let dry, and observe the formation of the chrome during evaporation. Make the coats not too thick. Between each dry pass, the surface can be polished with a piece of cotton to remove any dust or ‘flecks ».

DRYING

Chrome paint dries immediately, but it's advised to let stand to dry for at least 24h at ambient temperature. The longer it dries (up to 14 days), the more the chrome becomes harder and more resistant, which will allow an easier topcoating if you choose to clear.

The Chrome effect quality depends all on the gloss and hardness of the basecoat: the dryer is the basecoat, the better the chrome effect will be.

To achieve the best chrome effect, we recommend an extended basecoat drying time: The basecoat can dry from 2 to 14 days at room Temperature (20°C) and it can be cured with oven to accelerate the process, for exemple 60°C : 24h or up to 180°C / 30minutes

TOPCOATING

Topcoating requires a special technique: Spray 4 thin coats of our clearcoat HS 830 or of any type of topcoat that has been thinned, allow 1 to 2 minutes between each pass. Only after, clear normally. <the thinner the coats are, the skilfull and patient the painter is, the better the results.

The topcoat step is the critical step, as any liquid product apply over the chrome layer can modify the position of the micro chrome particules and destroy the moirror effect. one can keep 80% of the initial mirror effect or lose everything. So it is important to follow carefully the instructions above.

Also :

- About the chrome paint : the dryier the better : cook it (up to 150°C) or leave it dry fully for days.

TIP:

The following technique is excellent for topcoating the "chrome effect" paint with any type of clearcoat, without damaging the appearance, and to limit any "mirror effect" loss, which is due to solvents or the presence of water in the topcoat:

The chrome paint surface must be dry before it is heated very briefly with a gas flame. Some quick and brief passes just before clearcoating give very good result.

This same gas flame technique can be used just before the application of chrome paint: Indeed, once the glossy black paint (which serves as background/undercoat) is applied, this surface can be heated, for a very brief period and a few seconds before applying chrome.

Thus, the chrome paint adhesion is enhanced over the glossy black paint.

MIRROR EFFECT :

When sprayed over the inside of a hard, transparent and shiny surface, the chrome paint creates a mirror finish when viewed from the outside (glass, acrylic, polycarbonate, lexan)

Product in stock. Delivery: 48h

Questions from the clients, and answers :

"However, as soon as I painted the top coat with the colour of the paint (chrome) completely changed "

You simply need to take the time to read the instructions, especially about clearcoat .

All about the loss of mirror effect is explained and instructions are detailed

You need to let dry a few days at least or bake it

you can apply a flame with a torche before clearcoating to promote adhesion

you need to apply 4 super dry coats, spaced each of 2 minutes at least

then only you can apply the clearcoat normally with 2 wet coats

the dryer/thinner are you "flash coats", the more you will keep the chrome effect.

if on the contrary if one wets the chrome paint, the mirror effect vanishes

"I also noticed that the chrome paint was dusting off when you wipe it well with a micro fibre cloth. I.e. chrome paint was getting on the micro fibre, and the base coat of the rim was appearing."

1 - You can apply a soft cotton on the surface of the chrome paint to "polish" it and remove "scales". Nothing ells

2 - if you wipe the chrome paint , the chrome will disappear, it is normal as it is 3 - 5 µm thick.

If it goes it means that your gloss basecoat is hard and glossy. Note that you can improve adhesion of the chrome paint over the 2k basecoat glossy primer, by torching it with a gas flame. that is a secret tip to get adhesion over a non-sanded surface.

" the initial chrome effect was acceptable. However"

The chrome must be super nice. If it is only acceptable, then there is 2 causes for this deffect:

- basecoat is not dry/hard enough : allow more days of drying/curing or bake it.

- too much chrome paint has been applied.

- chrome coats have been sprayed too thick.

Why does the chrome effect fade when you polish?

Without the firing of a thin layer of chromium (5μm), solvents and liquids seep between the undercoat and the chrome and change the alignment and orientation of the chrome micro-flakes. Sufficient cooking avoids this phenomenon (150 ° / 20min or 80 ° C / 2h).

Find here our different complete CHROME paint kits:

► Motorcycle Kit

► Bicycle Kit

► Car Kit