All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

-

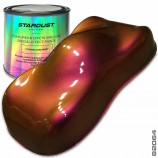

Special effect paints

- Chameleon effect paints

- Paint with an opalescent pearlescent sheen

- Prismatic Paints

- Candy Paints

- The fluorescent paints

- Phosphorescent paints

- Fluorescent paints UV

- Crystal Pearlescent Clearcoat

- Marble and crystal paint

- Paints that react to temperature

- Paints that react to light

- Magnetic paint and rust color

- Chrome effects

-

Our paint ranges for bodywork

-

PAINT KIT FOR CAR BODYWORK

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

- Primers for car paints

- Epoxy-polyester paint for wheel rim

- Spraypaint bodywork

- Metallic effect paints for car bodywork

- Tuning paints with effects

- Pearlescent paints for bodywork

- Solvent-based 1K base coats for cars

- 2K paints for cars

- Vintage cars paints

- Rustproof car frame paints

- Car underbodies and pick-up trucks paints

- Car cylinder block paints

- Dashboard paints

- Car brake paints

- Plastic bumper paints

- Car wing mirror paints

-

CAR COLOUR CODE

-

PAINT KIT FOR MOTORCYCLE BODYWORK

-

Motorcycle and scooter paint code - Can or spray paint

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

- Motorcycle tuning paints

- Motorcycle paint primers

- Motorcycle spray paints

- Epoxy paints for motorcycle frames

- Epoxy paints for motorcycle rims

- Metallic motorcycle paints

- Pearly motorcycle paints

- Motorcycle clearcoats

- The paints for plastic of cross country motorcycle

- Jet ski hull paints

- Paints for Quad

-

Motorcycle and scooter paint code - Can or spray paint

- Scooter fairing paints

- Helmet paints

- Auxiliary products

- Bicycle paints - Stardust Bike

- RAL Paint - Pantone Code

-

PAINT KIT FOR CAR BODYWORK

- Finish paints and topcoats

-

Artistic and custom specialties

- EPOXY RESINS

- Gilding with a gold leaf

- Pinstriping paint and brushes

- Hydrographic Film

- Covering car and motorcycle

- Pearls and Flakes bodywork

- Painting over the body

- Paint for fishing decoys

- Paints for guitars

- HIKARI : paints for models and miniatures

- Acrylic 3D Printing Paint – Primers, Colors, and Clearcoat

-

Bodywork accessories and consumables

- HVLP Spray Guns for car and motorcycle paints

- Our ranges of airbrushes

- Compressed air connections

- BODYWORK ACCESSORIES

- Abrasives for bodywork

- Buffing and polishing of bodywork

- Protective Equipment for painters

- POSTERS

- Paint air filters

- sample supports for paint tests

- Infrared and ultraviolet drying lamps for paint

- Bodywork adhesives and paint

- Air compressors for painting

- Paints for airbrush

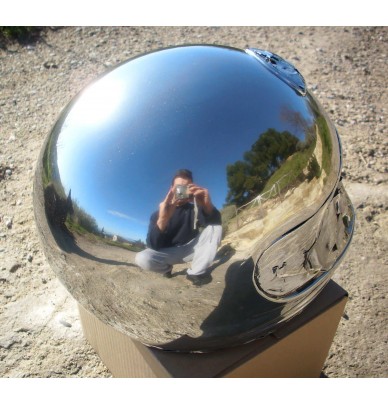

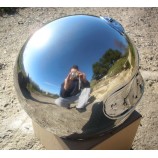

MIRROR-LIKE CHROME PAINT - COMPLETE KIT

New product

Kit including undercoat and topcoat

Includes: Undercoat with hardener / Chrome paint /Topcoat with hardener,

thinner

4 SIZES AVAILABLE:

1kg ~ 2kg ~ 4kg

Chrome effect paint complete kit - basecoat, chrome effect, topcoat

Chrome paint is the first product that imitates the closest chrome plating: the preparation is ultra-liquid and of a silver colour, created by evaporation. The imitation is surprising, a silvery plating of only a few microns thick that reflects like a mirror.

We manufacture a paint that is non-toxic, and cost effective thanks to its high concentration.

INSTRUCTIONS OF USE

As long as you follow carefully the instructions and that you are familiar with spraygun painting, you will succeed in applying this perticular product. It requires a simple spraygun (conventional and low pressure ones, airbrushes - select small nozzle size)

Overview :

The application is done in 3 coats

1. black paint + varnish

2. Chrome paint

3. varnish

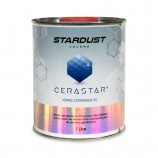

The use of ceramic varnish ST8900X both as BASE coat and TOP coat has important advantages, in addition to resistance:

This varnish provides high gloss and accelerated hardening.

In addition, it allows the creation of a hard-to-core bottom very quickly, which is necessary to achieve the mirror effect.

Conventional PU varnishes and lacquers have a core hardening 4 to 5 times slower.

To achieve the effect, step 1 should be as bright and as hard as possible.

Step 2, chrome plating, is easy : just apply a few thin coats.

Step 3 is varnishing for protection : it must be done with great care so as not to soak the chrome coat and keep the chrome effect intact.

SUPPORTS

Can be applied over any type of support: (Wood, Metal, Plastc..) prepared and necessarily covered with a primer.

RESULTS

Properly applied, the chrome effect is at its best when non topcoated.

For this reason, we recommend to apply clearcoat only when it's necessary. Indeed, when the chrome is topcoated, it will become dull, by the action of solvents. A skilfull and patient painter will achieve without difficulty a beautiful topcoated chrome effect. To clear without following the instructions will remove the chrome finish.

RESISTANCE

Without clearcoat: the paint is sensitive to scratches and friction

Topcoated, it becomes resistant to abrasion, liquids and chemical products like any automotive car body. NOTE : Given that chrome paint is applied over a background that has not been sanded, it’s not guaranteed against any peeling due to tearing or due to an important shock.

Chrome paint manufactured by StardustColors doesn't yellow and tarnish. It resists to prolonged exposure to temperatures as high as 250°C.

Important Tip: To help promote adhesion with the glossy black background, a rapid flame treatment can be performed (passing briefly the gas flame 1 or 2 times) just prior to the application of the chrome paint. Similarly, to facilitate chrome topcoating without losing the mirror-like effect, a brief flame treatment can be carried out on chrome painting before applying the clearcoat.Important Tip: To help promote adhesion with the glossy black background, a rapid flame treatment can be performed (passing briefly the gas flame 1 or 2 times) just prior to the application of the chrome paint. Similarly, to facilitate chrome topcoating without losing the mirror-like effect, a brief flame treatment can be carried out on chrome painting before applying the clearcoat.

INDUSTRIAL VERSION :

StardustColors proposes an industrial chrome paint system, that provides excellent adhesion and accelerated implementation through baking.

There are countless application possibilities: Equipment, mobile, bottles, decoration, etc.

Find out more about the system here

CHROME CANDY :

By adding transparent shades (see Section CANDY) to the topcoat, you can colour the chrome as you wish.

MIRROR EFFECT:

Painted on the inside of a transparent support, such as a window or other, it will create a reflection like a mirror.

COVERAGE:

1kg / 1,5 sqm 2kg / 3 sqm 4kg/ 6 sqm

VOC : > 420g/L

Kit including

1kg : (1 – 1,25m²)

250 ml basecoat black + 250 ml varnish 8900X + 250ml hardener H440 + 250ml chrome paint

2kg : (2 – 2,5 m²)

500 ml basecoat black + 500 ml varnish 8900X + 500ml hardener H440 + 500ml chrome paint

4kg : (4 – 5 m² )

1L basecoat black + 1L varnish 8900X + 1L hardener H440 + 1L chrome paint

METHOD AND ADVICE :

4-steps process to follow : black basecoat, Clearcoat, Chrome Paint, Clearcoat

The same ST8900X varnish is used as a base and as a varnish.

1. Apply the undercoat:

-

The "undercoat" is a black, glossy and hard background, which is achieved with a black paint and a varnish :

-

Apply the black basecoat (ready-to-use, pre-diluted paint) with 2 or 3 thin coats.

-

After 20 minutes drying time, apply 8900X varnish (mix with hardener 1:1 i.e. 100 parts varnish + 100 parts hardener). Do not dilute.

-

Apply 1 shiny coat.

Leave to dry between 1/2 day and 10 days. The results obtained with a long drying time are a more refined mirror effect, thanks to the hardening of the undercoat. You get 75% of the hardening in half a day.

2. Shake well the chrome before use (the product is ready for use). Set up a medium pressure and spray successive very thin passes (around 5). It's important to have very thin coats (press slightly on the trigger) and never apply thick coats. Allow to dry a few seconds between each pass and watch the chrome’s formation during the evaporation that happens in a few seconds. Let dry at room temperature for at least 48h. The more you let dry, (up to 14 days), the harder and the more resistant becomes the chrome, which will allow an easier topcoating, if needed. Baking possible.

3. Topcoating is not necessary and intended for parts that are subject to abrasion and outdoors conditions such as rain. For pieces that stay indoors and that are not subject to repeated contacts and friction, we don't recommend to clear them: without the clearcoat, you will achieve a maximum chrome aspect.

Instructions: Apply our topcoat varnish 8900X (mixture with hardener 1:1 i.e. 100 parts varnish + 100 parts hardener). Do not dilute: Begin by 4 passes extremely dry, allowing 1 to 2 minutes between each depending of the temperature. And only after apply normally the topcoat. The final result will depend of the thinness of the passes, but as well of the skill and patience of the painter.

Tips:

The Chrome effect quality depends all on the gloss and hardness of the basecoat: the dryer is the basecoat, the better the chrome effect will be.

To achieve the best chrome effect, we recommend an extended basecoat drying time: The basecoat can dry from 2 to 14 days at room Temperature (20°C) and it can be cured with oven to accelerate the process, for exemple 60°C : 24h or up to 180°C / 30minutes

Find here our different complete CHROME paint kits:

► Motorcycle Kit

► Bicycle Kit

► Car Kit

Accessories

14 other products in the same category

SPRAY CAN GRIP HANDLE

8.53£

8.53£

WE ALSO RECOMMEND YOU

Recently Viewed

- Special Effect Paints

- Chrome Effect

-

Car and motorcycle paint

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

.

.

.

-

MOTO COLOUR CODE

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

.

.

-

CAR COLOUR CODE

- Finish Paints and Topcoats

-

Specialties

-

Accessories and consumables

.

.

- AIRBRUSH PAINT

- COLORCHART