All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

NeoChrome Anti-Corrosion Paint for Exterior Use

New

Chrome effect anti-corrosion paint for exterior use

Cold galvanisation with chrome finish for all substrates

OEM / industrial / architectural quality

Direct application on glass and plastic

Easy to paint (sponge/airbrush/spray gun) and to varnish

Offers and Packaging

Paint in cans: 125ml – 250ml – 500ml – 1L – 5L

Paint in aerosol spray: 400ml

NeoChrome is a metallisation solution that delivers an exceptional mirror effect by spraying.

It is particularly suited to applications requiring high levels of corrosion resistance and durability.

NeoChrome® – the paint that is easy to apply and easy to varnish

|

Three-step NeoChrome anti-corrosion paint system |

|

Step 1 – Ceramic Clearcoat |

Step 2 – NeoChrome |

Step 3 – Ceramic Clearcoat |

Innovation: an innovative chrome paint for automotive, architectural or industrial applications

Based on a rare metal, NeoChrome produces a mirror effect equivalent to that of silver (metallisation by silvering). However, unlike silver – which is sensitive to oxidation and UV – or even aluminium, NeoChrome offers the advantages of easy application and a very high level of resistance to corrosion from water, weather and UV rays.

Varnishing

Varnishing can be done using any clear and glossy Clearcoat, without any difficulty or special technique, and without loss of the mirror effect.

Fields of application

NeoChrome is a chrome-effect paint suitable for professional and industrial applications in the automotive, decorative, and architectural sectors, for both indoor and outdoor use.

NeoChrome is a highly transparent and conductive paint that can also be applied to glass. It is also suitable for certain shiny, hard plastics and resins.

Product Nature :

Solvent-based single-component paint

Second stage of the NeoChrome paint system (base / chrome / Clearcoat)

Application method :

-

By dabbing with a sponge

-

By spraying (for best results), using an airbrush from 0.2 mm or a pneumatic spray gun up to 1.4 mm

Substrate :

Apply over 2K glossy Ceramic Clearcoat ST8900X (2L kit or 1L kit), dried for at least 12 hours.

Application possible on all types of primed and/or prepared substrates and materials (concrete, wood, metals, etc.), directly on glass, and certain plastics (ABS, PET, PS).

Application using spray gun or airbrush:

Step 1 – On a white/grey/black base colour* (paint or primer ), apply an ultra-glossy and ultra-hard 2K paint : Allow for a full internal cure over several days. The best result is obtained using our ultra-fast curing Ceramic Clearcoat ST8900X, with a minimum drying time of 12 hours.

Step 2 – Degrease with a wipe and isopropyl alcohol to achieve a perfectly clean surface, then apply NeoChrome paint in 2 to 3 light coats.

Optional: Drying/Baking – we recommend 1h at 20°C or 20 min at 60°C before applying the Clearcoat. IR drying possible: 5 to 10 min.

Step 3 - Apply a glossy Clearcoat. We recommend Clearcoat ST8900X for an ultra-resistant and glossy finish. The Clearcoat can be applied quickly and easily, with no loss of mirror effect, using an airbrush or spray gun, with one or two light coats followed by a full glossy coat.

*Base colour : we recommend a white base for best results.

On a black base, the result will appear slightly darker.

Application using 400ml aerosol version

Step 1 – On a white/grey/black base colour (paint or primer), apply the 2K UHS830 Clearcoat in aerosol : Allow for a full 7-day drying period.

Step 2 – Degrease with a wipe and isopropyl alcohol, then apply NeoChrome spray paint in several very fine and quick coats.

Drying: 1h at 20°C

Step 3 - Apply the UHS830 Clearcoat in aerosol.

Apply two very fine coats (quick passes from 30 cm away), with 1–2 minutes drying between coats, followed by one full glossy coat.

Glass chrome coating – Mirror creation :

NeoChrome adheres directly and strongly to glass. It is therefore possible to create mirrors by spraying the paint on the internal face of a clean and degreased mirror. A white paint coat is then applied to create opacity..

Plastic chroming

Can be applied directly to certain shiny plastics* (PET, ABS). Not suitable for (PVC, PC).

*Tests should be carried out on various types of glossy plastic to confirm compatibility before final application.

High resistance to weather and atmospheric corrosion

NeoChrome is based on a rare metal that is highly resistant to corrosion. It can be submerged in water without a Topcoat for one month without corroding.

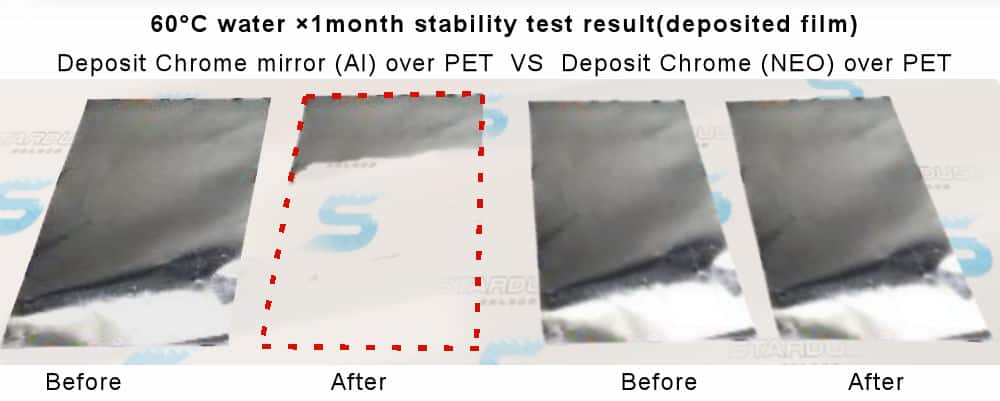

Water resistance test result: 60°C × 1 month (film applied: no degradation)

No UV yellowing

Comparison test between aluminium coating and NeoChrome coating on PET plastic

Safety :

Flammable product, cannot be shipped by air. Solvent-based (harmful).

Contains no chromium (Cr), its derivatives, or any substances of concern (SVHC, CMR)

Technical characteristics

Temperature resistance: 125°C

Appearance: brownish grey liquid

Dry film thickness: 2μm

Coverage: 7–8 m² / Litre

Density: 0.88 kg / L

VOC >420g/L

Application tip using sponge

Use a low-density sponge, soaked with enough product to allow application of a thick coat in a single pass, moving left to right across the surface.

Apply the product without retouching or overlapping coats.

Allow the product to evaporate. After evaporation, if there are any areas with insufficient product, a touch-up can be done.

By applying a new coat, any flaws can be covered.

NeoChrome® is a registered European trademark of StardustColors.