All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

Applying paints with spray guns

Applying paints with spray guns

Spraying paint with a pneumatic spray gun involves atomizing a mixture of air and paint using a nozzle, which is the primary component of spray guns.

The advantage of using a spray gun is that paint is applied evenly with an air jet, without ever touching the surface, which prevents marks and speeds up drying time.

All modern spray guns are double-action, meaning that the trigger allows the user to:

Spray only air (by pressing the trigger lightly, at about 10–20% pressure).

Spray air + paint when the trigger is fully engaged.

There is a noticeable click and a difference in trigger resistance when transitioning from air-only spraying to air + paint spraying.

The trigger also controls the amount of paint being released, depending on how much pressure is applied.

Used in automotive bodywork, as well as in construction for painting ceilings using airless spray guns, spray painting is also common for structures and frameworks. It is a far more efficient and faster method compared to using a roller or brush, producing an unmatched finish.

Basic rules and principles of spray painting

Horizontal spraying without Overlapping

Unlike other painting methods, spray painting must be done with a left-to-right and right-to-left motion. The layers should never be cross-applied horizontally and vertically when using a spray gun.

The Back-and-Forth Motion

Typically, a single layer is applied in a back-and-forth movement.

Additionally, when spraying paint or clear coat, each new layer should overlap the previous one by half while spraying upward or downward.

► Rule #1: The key to mastering spray painting is having a flexible wrist, capable of following the surface contours smoothly. The spray gun must always remain perpendicular to the surface.

► Rule #2: The spray gun must always be in motion while spraying.

► Rule #3: Respect the four essential parameters: speed / distance / angle / air pressure. These determine the amount of paint or clear coat applied to the surface.

► Rule #4: At the end of each pass, when reaching the edge of the surface, the spray gun must change direction. At this point, the painter should release the paint spray momentarily, allowing only air to flow.

The importance of rule number 4: Spray Gun Positioning

Proper positioning ensures even coverage and prevents paint buildup at the edges.

Airflow and Pressure Control

To achieve a dry film of the correct thickness with accurate color, it is crucial to have a balanced air-to-paint ratio. Technique alone is not enough!

The airflow rate is directly related to the air pressure (measured in bars or PSI) inside the hose.

When painting large surfaces (such as an entire vehicle), the air supply (m³/h) must be stable. A sufficiently large compressor is essential to maintain consistent airflow and pressure.

It is always possible to follow the technical data sheet of the product being used.

Example: 2.5–3 bars / nozzle size: 1.4mm.

A specific nozzle size is recommended based on the product's viscosity and thickness. The air pressure is adjusted using the pressure gauge at the compressor’s outlet.

However, these are only recommendations—the painter is free to adjust settings as needed.

Before starting a job, it is advisable to test spray settings. Based on nozzle size, paint dilution, and workpiece size, the painter can fine-tune the spray gun and air pressure for optimal results:

→ If air pressure is too low, the applied layer will be too thin, resulting in a transparent paint or a clear coat lacking gloss.

→ If air pressure is too high, the paint will be sprayed too forcefully, leading to paint loss through overspray, as well as defects in the wet paint film (e.g., marbling, powdering).

Spray Painting Different Products

In automotive bodywork, spray painting reaches its highest level of skill during clear coat application. Achieving a flawless, glossy finish is always a delicate task, even for an experienced painter.

Intermediate Level: Applying basecoats is significantly easier, as it only requires thin, repeated layers until the surface is fully covered.

Beginner Level: Applying primers is the least challenging, as these are high-build products that are less sensitive to application technique.

Spraying Water-Based vs. Solvent-Based Paints

Solvent-based paints are easier to spray than water-based paints. They are more fluid and dry faster.

Water-based paints are thicker and cannot be freely diluted as solvent-based paints can. They require higher air pressure for spraying, and because they evaporate more slowly, longer flash-off times are needed between coats. Additionally, airflow assistance is necessary to accelerate drying.

HVLP Spray Guns for Automotive Painting

HVLP Spray Guns for Automotive Painting

There are two main types of spray guns used in automotive bodywork : HPLV (High Pressure Low Volume)

HVLP (High Volume Low Pressure)

HVLP guns are the industry standard today, offering an optimal paint transfer rate, meaning less paint consumption and minimal overspray.

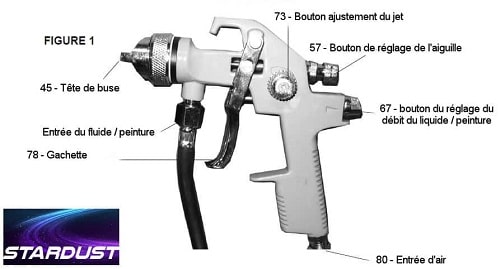

Today, a body spray gun is necessarily an HVLP. It includes a paint cup, a handle, a trigger, a nozzle and a needle. Two to three adjustment knobs (for air pressure, spray pattern, and needle control).

You are starting in painting and want to know which HVLP spray gun to choose ? A bad painter using a high-end spray gun will still get poor results, while a skilled painter can achieve perfect results with a budget spray gun!

Various pneumatic Spray Guns

There are spray guns without paint cups, which operate via suction rather than gravity feed.

Some versions include pressurized tanks, which are particularly useful in challenging conditions, as they allow the gun to be used in any orientation, even upside-down!

There are also specialized pneumatic spray guns, such as dual-nozzle guns, which are reserved for silvering or liquid metal applications.

Chroming machines

Spraying Paint with Aerosol Cans

Spraying Paint with an airbrush