All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

-

Special effect paints

- Chameleon effect paints

- Paint with an opalescent pearlescent sheen

- Prismatic Paints

- Candy Paints

- The fluorescent paints

- Phosphorescent paints

- Fluorescent paints UV

- Crystal Pearlescent Clearcoat

- Marble and crystal paint

- Paints that react to temperature

- Paints that react to light

- Magnetic paint and rust color

- Chrome effects

-

Our paint ranges for bodywork

-

PAINT KIT FOR CAR BODYWORK

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

- Primers for car paints

- Epoxy-polyester paint for wheel rim

- Spraypaint bodywork

- Metallic effect paints for car bodywork

- Tuning paints with effects

- Pearlescent paints for bodywork

- Solvent-based 1K base coats for cars

- 2K paints for cars

- Vintage cars paints

- Rustproof car frame paints

- Car underbodies and pick-up trucks paints

- Car cylinder block paints

- Dashboard paints

- Car brake paints

- Plastic bumper paints

- Car wing mirror paints

-

CAR COLOUR CODE

-

PAINT KIT FOR MOTORCYCLE BODYWORK

-

Motorcycle and scooter paint code - Can or spray paint

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

- Motorcycle tuning paints

- Motorcycle paint primers

- Motorcycle spray paints

- Epoxy paints for motorcycle frames

- Epoxy paints for motorcycle rims

- Metallic motorcycle paints

- Pearly motorcycle paints

- Motorcycle clearcoats

- The paints for plastic of cross country motorcycle

- Jet ski hull paints

- Paints for Quad

-

Motorcycle and scooter paint code - Can or spray paint

- Scooter fairing paints

- Helmet paints

- Auxiliary products

- Bicycle paints - Stardust Bike

- RAL Paint - Pantone Code

-

PAINT KIT FOR CAR BODYWORK

- Finish paints and topcoats

-

Artistic and custom specialties

- EPOXY RESINS

- Gilding with a gold leaf

- Pinstriping paint and brushes

- Hydrographic Film

- Covering car and motorcycle

- Pearls and Flakes bodywork

- Painting over the body

- Paint for fishing decoys

- Paints for guitars

- HIKARI : paints for models and miniatures

- Acrylic 3D Printing Paint – Primers, Colors, and Clearcoat

-

Bodywork accessories and consumables

- HVLP Spray Guns for car and motorcycle paints

- Our ranges of airbrushes

- Compressed air connections

- BODYWORK ACCESSORIES

- Abrasives for bodywork

- Buffing and polishing of bodywork

- Protective Equipment for painters

- POSTERS

- Paint air filters

- sample supports for paint tests

- Infrared and ultraviolet drying lamps for paint

- Bodywork adhesives and paint

- Air compressors for painting

- Paints for airbrush

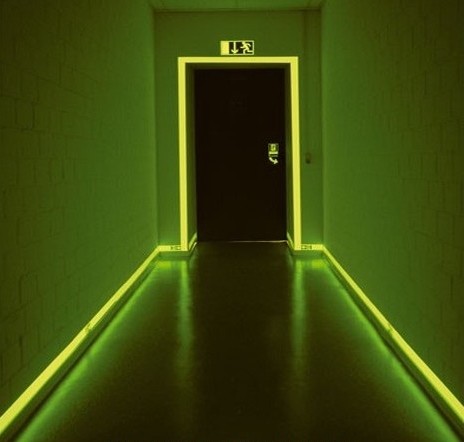

Phosphorescence at the service of signaling

Phosphorescence at the service of signaling

In the field of dark marking, signage, we can say that phosphorescent paint is not a modern and very recent product, because did you know, we find their use already 80 years ago, in German bunkers. Already, we knew and used the properties of phosphorescent paint for safety, marking and guidance in the event of absence of light. Phosphorescent signaling paints have the advantage of being applied to all surfaces, floors, walls, machines...

We are not talking about strips or other panels here, but only paint. This option is necessary in certain cases, in conditions where it is not possible to stick a band or a signal because of the shape of the support, or when a very high level of resistance is desired, for example at sea water, or the passage of machines on the ground.

The special paint option certainly requires much more work than the simple fact of peeling off the label and putting it up on a wall: you have to clean the support, apply a coat of white primer, then go from 3 to 4 coats, respecting the drying time!

Which phosphorescent paint for safety ?

With the rare exception of certain special requirements (in hospitals or schools for example), ultra-resistant and high-performance paint qualities are used. Depending on the installation outdoors or indoors, on floors or walls, two-component polyurethane or epoxy type paints are preferred.

These coatings, very hard and durable, are able to withstand conditions in industrial, professional, public environments, for example pedestrian traffic or the passage of machinery, or spraying with chemicals such as acids , detergents, fuels.

A good phosphorescent paint for safety must have excellent adhesion to its support: for example in a train, if this layer of paint does not hold sufficiently, it will quickly be peeled off by users. Photo-luminescent signaling paints also have the obligation to maintain a good level of performance to ensure the safety of the public or workers. It must be possible to clean, wash and scrub phosphorescent safety paints to keep them in optimal working order. For this, they undergo resistance tests with alcohols and solvents.

Polyurethane phosphorescent paint

Polyurethane phosphorescent paint

Polyurethane often refers to a two-component paint, which is cured chemically, not by evaporation or air drying. They are exceptionally strong and suitable for all uses. Phosphorescent polyurethane paint has another advantage, it perfectly tolerates exposure to the sun, without yellowing.

Make a phosphorescent floor paint

We are mainly talking about parking floors or industrial buildings, so concrete floors. Other types of floors (wood, resin, carpet, paint, etc.) are less common. However, there is always a solution to paint them. To make a phosphorescent floor paint, it is necessary to make strips 2.5 to 10 cm wide, continuous or dotted. We explain the different steps to follow to create phosphorescent floor markings with paint.

How to paint a floor with phosphorescent paint ?

It is rare to paint the entire surface of a floor. In general, for those who are wondering why, and how to paint a floor with phosphorescent paint, know that it is essentially bands, lines, markings, arrows that are painted on floors of various kinds. There's even the Helicopter Glow In The Dark Landing Floor Paint Case!

Phosphorescent paint for car bodywork

Phosphorescent paint for decoration and hobbies and crafts

Phosphorescent for the bike

- Special Effect Paints

- Chrome Effect

-

Car and motorcycle paint

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

.

.

.

-

MOTO COLOUR CODE

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

.

.

-

CAR COLOUR CODE

- Finish Paints and Topcoats

-

Specialties

-

Accessories and consumables

.

.

- AIRBRUSH PAINT

- COLORCHART