All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

-

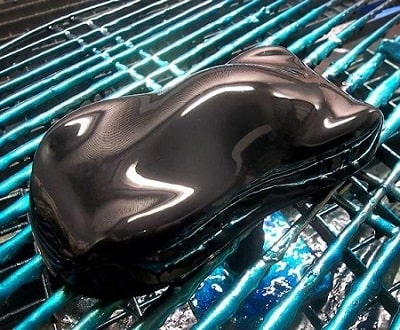

Special effect paints

- Chameleon effect paints

- Paint with an opalescent pearlescent sheen

- Prismatic Paints

- Candy Paints

- The fluorescent paints

- Phosphorescent paints

- Fluorescent paints UV

- Crystal Pearlescent Clearcoat

- Marble and crystal paint

- Paints that react to temperature

- Paints that react to light

- Magnetic paint and rust color

- Chrome effects

-

Our paint ranges for bodywork

-

PAINT KIT FOR CAR BODYWORK

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

- Primers for car paints

- Epoxy-polyester paint for wheel rim

- Spraypaint bodywork

- Metallic effect paints for car bodywork

- Tuning paints with effects

- Pearlescent paints for bodywork

- Solvent-based 1K base coats for cars

- 2K paints for cars

- Vintage cars paints

- Rustproof car frame paints

- Car underbodies and pick-up trucks paints

- Car cylinder block paints

- Dashboard paints

- Car brake paints

- Plastic bumper paints

- Car wing mirror paints

-

CAR COLOUR CODE

-

PAINT KIT FOR MOTORCYCLE BODYWORK

-

Motorcycle and scooter paint code - Can or spray paint

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

- Motorcycle tuning paints

- Motorcycle paint primers

- Motorcycle spray paints

- Epoxy paints for motorcycle frames

- Epoxy paints for motorcycle rims

- Metallic motorcycle paints

- Pearly motorcycle paints

- Motorcycle clearcoats

- The paints for plastic of cross country motorcycle

- Jet ski hull paints

- Paints for Quad

-

Motorcycle and scooter paint code - Can or spray paint

- Scooter fairing paints

- Helmet paints

- Auxiliary products

- Bicycle paints - Stardust Bike

- RAL Paint - Pantone Code

-

PAINT KIT FOR CAR BODYWORK

- Finish paints and topcoats

-

Artistic and custom specialties

- EPOXY RESINS

- Gilding with a gold leaf

- Pinstriping paint and brushes

- Hydrographic Film

- Covering car and motorcycle

- Pearls and Flakes bodywork

- Painting over the body

- Paint for fishing decoys

- Paints for guitars

- HIKARI : paints for models and miniatures

- Acrylic 3D Printing Paint – Primers, Colors, and Clearcoat

-

Bodywork accessories and consumables

- HVLP Spray Guns for car and motorcycle paints

- Our ranges of airbrushes

- Compressed air connections

- BODYWORK ACCESSORIES

- Abrasives for bodywork

- Buffing and polishing of bodywork

- Protective Equipment for painters

- POSTERS

- Paint air filters

- sample supports for paint tests

- Infrared and ultraviolet drying lamps for paint

- Bodywork adhesives and paint

- Air compressors for painting

- Paints for airbrush

Hydro varnishes

Hydro varnishes

We have classified them as special varnishes because surprisingly, these water-based varnishes are considered rare and special in the professional painting world, since the standard and most of the existing offers are based on formulas of solvent-based varnish.

Indeed, water-based varnishes have until now had a bad reputation among applicators, in all professional fields: so-called water-soluble varnishes are known to be less shiny, much less resistant and less easy to apply. than traditional solvent-based polyurethane varnishes. Well all that changes!

OK, we remember the bitter failures of the chemists of the automotive industry and the European politicians, supposedly anxious to establish rules favoring the ecology, with the revolutionary water-based finishes, which were turned out to be a fiasco. There is total silence on this subject in the world of bodywork. However, in recent years we have seen the release of new high-performance acrylic products!

The differences between water-based and solvent-based varnishes

Basically, the difference is mainly the solvent : in a "solvent-free" product, water is mainly used to dilute, dissolve and evaporate the polymers from manufacture, through application and up to to evaporation. In the solvent-based product, organic solvents are used. The same acrylic resins are used and we know that this resin family shows the best resistance to the sun and bad weather! The main defect of water is its slow evaporation, which delays drying and makes application difficult, but also its poor compatibility with many chemical additives.

In water-based varnishes (we are talking about resistant and efficient professional varnishes... not water-based varnishes for schoolchildren !), we therefore use co-solvents : these are mild solvents, universally compatible products which, through a kind of “sleight of hand”, allow all these different chemicals to be mixed together. There are now 2-component acrylic polyurethane water-based varnishes developed by Stardust and which open a new path in the field of ecological finishes.

The coalescence of water-based varnishes

The coalescence of water-based varnishes

You can think of polymers (the solid resin) as little bubbles or cells floating in water, which keeps them wet, liquid and mobile. The phenomenon of coalescence is the bursting and welding between these bubbles, which will allow hardening. This is enabled by the evaporation of the solvent (water) and is aided by the presence of water-compatible solvents which allow this acrylic dry matter to be welded.

The use of water-based varnishes

First of all, we use these products when we have obligations in terms of respecting the emission of polluting materials (VOCs). These water-based products are used in applications, generally with cooking, in the fields of food, packaging or certain standards impose non-hazardous products. Similarly, water-based products provide solutions when it is necessary to apply in closed places, where solvent fumes or flammable products are prohibited.

Varnish to standards

Technical varnish

Specific protective varnish

Varnish with special effects

Textured varnish

- Special Effect Paints

- Chrome Effect

-

Car and motorcycle paint

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

.

.

.

-

MOTO COLOUR CODE

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

.

.

-

CAR COLOUR CODE

- Finish Paints and Topcoats

-

Specialties

-

Accessories and consumables

.

.

- AIRBRUSH PAINT

- COLORCHART