All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

-

Special effect paints

- Chameleon effect paints

- Paint with an opalescent pearlescent sheen

- Prismatic Paints

- Candy Paints

- The fluorescent paints

- Phosphorescent paints

- Fluorescent paints UV

- Crystal Pearlescent Clearcoat

- Marble and crystal paint

- Paints that react to temperature

- Paints that react to light

- Magnetic paint and rust color

- Chrome effects

-

Our paint ranges for bodywork

-

PAINT KIT FOR CAR BODYWORK

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

- Primers for car paints

- Epoxy-polyester paint for wheel rim

- Spraypaint bodywork

- Metallic effect paints for car bodywork

- Tuning paints with effects

- Pearlescent paints for bodywork

- Solvent-based 1K base coats for cars

- 2K paints for cars

- Vintage cars paints

- Rustproof car frame paints

- Car underbodies and pick-up trucks paints

- Car cylinder block paints

- Dashboard paints

- Car brake paints

- Plastic bumper paints

- Car wing mirror paints

-

CAR COLOUR CODE

-

PAINT KIT FOR MOTORCYCLE BODYWORK

-

Motorcycle and scooter paint code - Can or spray paint

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

- Motorcycle tuning paints

- Motorcycle paint primers

- Motorcycle spray paints

- Epoxy paints for motorcycle frames

- Epoxy paints for motorcycle rims

- Metallic motorcycle paints

- Pearly motorcycle paints

- Motorcycle clearcoats

- The paints for plastic of cross country motorcycle

- Jet ski hull paints

- Paints for Quad

-

Motorcycle and scooter paint code - Can or spray paint

- Scooter fairing paints

- Helmet paints

- Auxiliary products

- Bicycle paints - Stardust Bike

- RAL Paint - Pantone Code

-

PAINT KIT FOR CAR BODYWORK

- Finish paints and topcoats

-

Artistic and custom specialties

- EPOXY RESINS

- Gilding with a gold leaf

- Pinstriping paint and brushes

- Hydrographic Film

- Covering car and motorcycle

- Pearls and Flakes bodywork

- Painting over the body

- Paint for fishing decoys

- Paints for guitars

- HIKARI : paints for models and miniatures

- Acrylic 3D Printing Paint – Primers, Colors, and Clearcoat

-

Bodywork accessories and consumables

- HVLP Spray Guns for car and motorcycle paints

- Our ranges of airbrushes

- Compressed air connections

- BODYWORK ACCESSORIES

- Abrasives for bodywork

- Buffing and polishing of bodywork

- Protective Equipment for painters

- POSTERS

- Paint air filters

- sample supports for paint tests

- Infrared and ultraviolet drying lamps for paint

- Bodywork adhesives and paint

- Air compressors for painting

- Paints for airbrush

Pearls and pigments for epoxy resin

New product

Metallic pearl and pigment powders for mixing in epoxy resin

(5 series of pearl pigments to choose from)

25g pots

Order shipped the same day if placed before 1 p.m. by GLS or Chronopost

Other packagings from 1kg to 25kg available - Contact us by email

Powders, pearls and flakes for epoxy resin :

The pearl and metallized pigments are incorporated into the epoxy resin to give beautiful iridescent effects, especially for making the famous epoxy river tables, but also marbled epoxy floor resins, for example.

These pearl powders reflect the light and sparkle when added to the epoxy resin.

The particles are light and therefore very concentrated :

5 to 25g are enough to tint 1L of epoxy resin

Being light, they do not fall back and remain in suspension once mixed in the resin.

A myriad of choices of colours and effects to achieve epoxy castings :

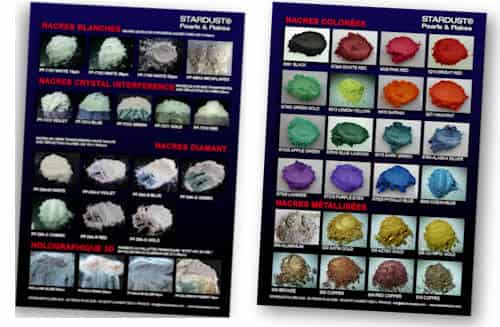

Discover all our effect pearls for epoxy resin :

(sizes in microns µm) all delivered in 25g pots

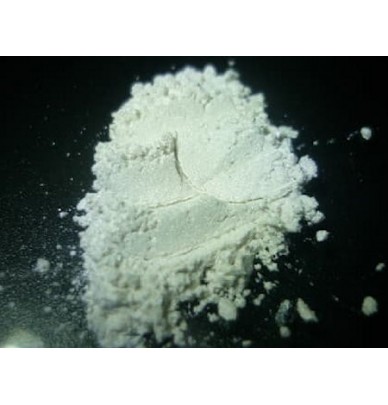

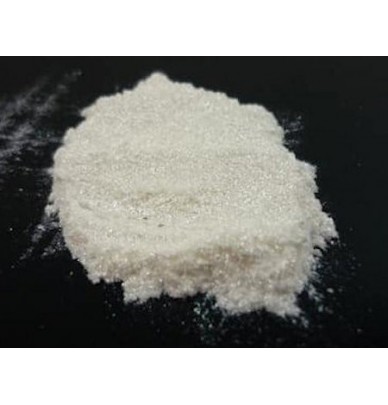

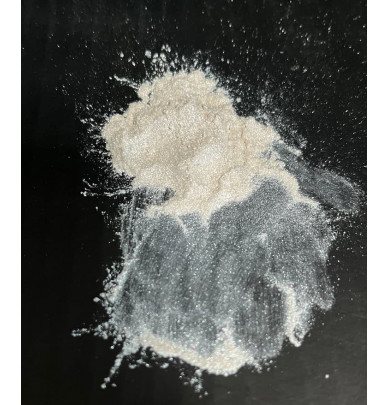

- series of 4 basic white pearls (fine or coarse are available)

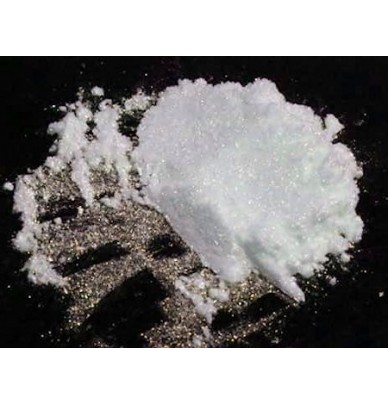

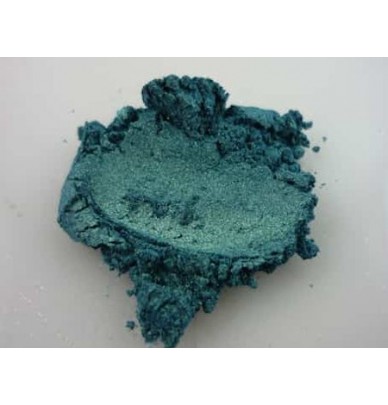

- series of 16 coloured pearls (commonly used in epoxy river tables)

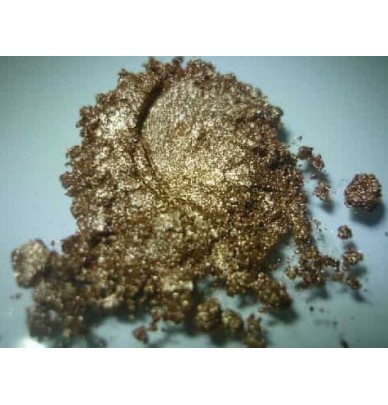

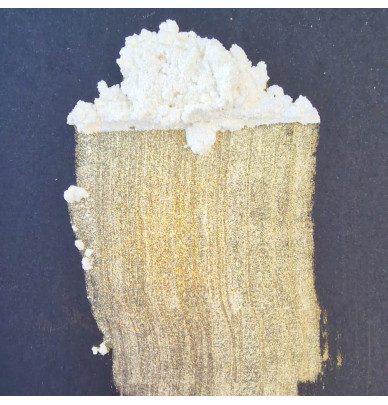

- series of 8 metallic pearls (metallic shades)

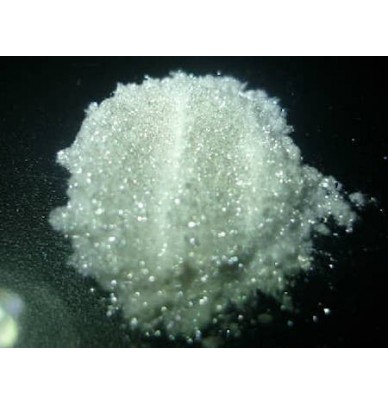

- series of 7 Diamond pearls (extra glitter)

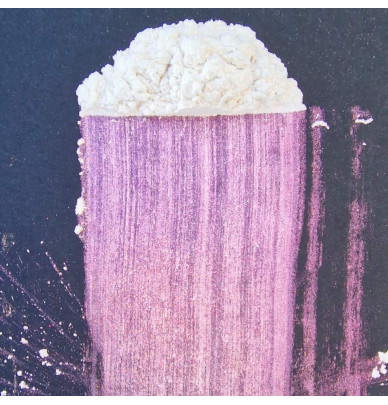

- series of 8 Interferences pearls 10-60µm

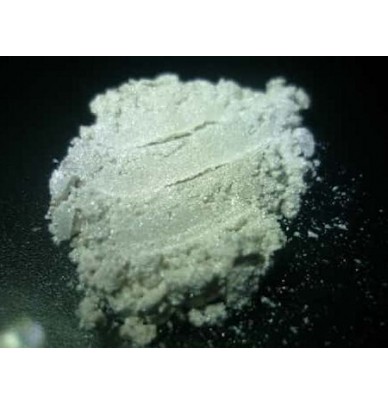

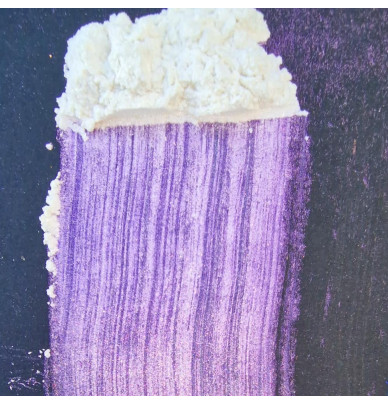

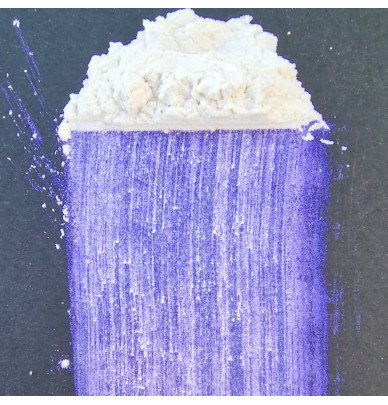

Some pearls are coloured and semi-opaque, while others are transparent and have the appearance of white powders.

These transparent pearls reflect a specific colour when observed under light or on a dark background, and are called "interfering"

Use and mixing of pearls in epoxy resins :

Add 25g max per liter of mixed resin and stir. There is no point to stir vigorously, simply disperse the pearls in the resin.

The pearl quantity depends mainly on the thickness of the casting: the lower the thickness, the more one must charge in pearls (up to 5%). On the contrary, for larger thicknesses, it is possible to reduce the pearl content to 0.1% (i.e. 10g/L)

When making a "river table", it is useful to have a dark background if you work with small layer thickness, because the nacres have little opacifying effect, and can be seen through.

Descriptions of the pearls and their effects :

Download the colour chart at the bottom of the page

White pearls (from 5µm to 2mm) :

They have the appearance of white powder, and create pure transparent white pearl effects. The smaller the size, the more the white satin effect, and the larger the size, the more gloss the effect.

They are semi transparent and produce a white effect on a white background, and a silver effect on a black background.

The pearl pigments can be tinted with translucent epoxy inks.

Dosage indications 25/L

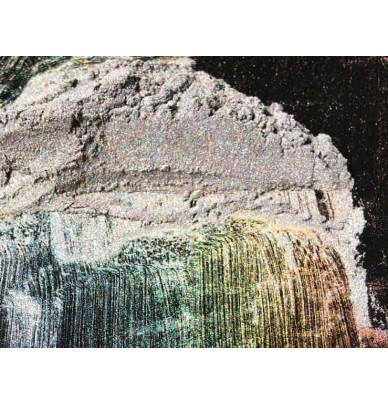

Coloured pearls (60µm) :

Coloured pearl powder, medium size pearls, easy to use and efficient, they are frequently chosen to make the epoxy pourings for "river tables".

They give better results on a dark or black background, except if the thickness of the epoxy casting is 5cm or more

Dosage indications 25/L

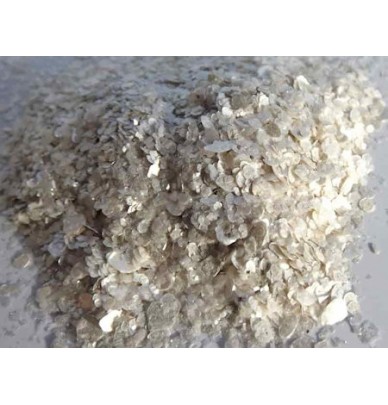

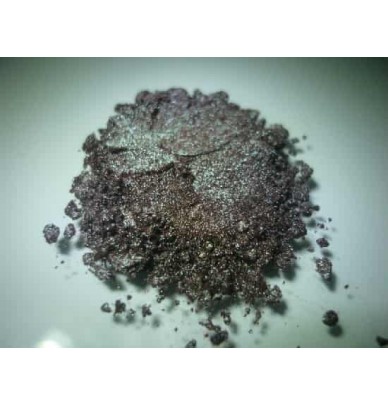

Metallic pearls (60µm) :

They are pearls that provide a gold or copper aspect, obtained by depositing a thin layer of metallisation on the mica flakes. They are semi-opaque and give beautiful effects when mixed with epoxy resins, especially to make castings in the wood grooves :

Dosage indications : from 5 to 25g/L

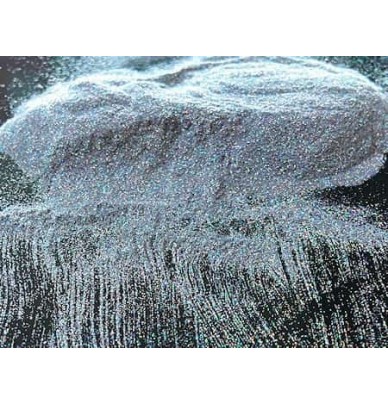

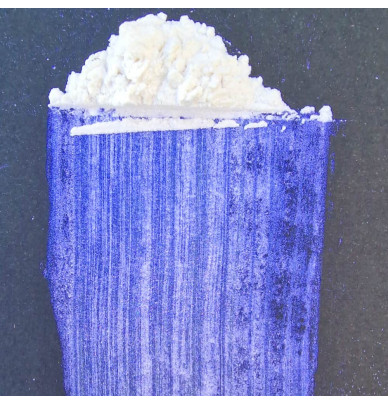

Diamond pearls (100µm) :

Special pearls made from medium size (100µm) glass micro particles. They are high quality products, with strong reflectory properties: delivered as white pearlescent powder, the Diamond pearls are transparent. In the light, they produce extra iridescent colourful reflections.

They give best results on black or coloured backgrounds. On a white background, they create opalescent reflections.

Dosage indications : from 5 to 25g/L

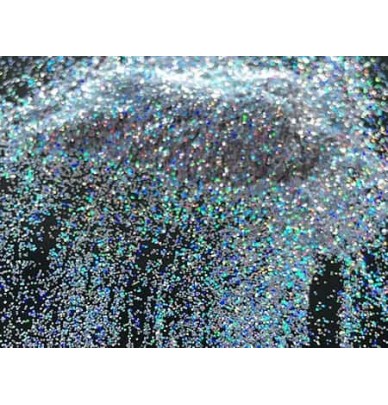

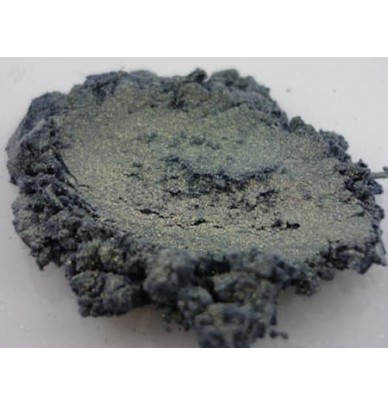

Holographic pigments (from 20 to 200µm) :

Delivered as a grey powder, produced from polyester or aluminum depending on the type and size of the pigments, these effect pigments reflect a full rainbow effect, the colour of which varies according to the position of the observer.

Best results obtained on dark or black backgrounds. Mixture from 5 to 25g/L, in thin or superficial passes (example with 4000 glaze epoxy resin)

Use of pearls or pigments in floor resins :

Stardust® pearls can be used to create beautiful marbled and pearlescent effects in resin floors (whether PU, epoxy or others). They are mixed directly within the mass of the resin, or in a more concentrated portion of resin that is previously applied working in a “net” pattern, before casting the big part of resin. Mixing is possible only in transparent resin.

Learn more :

Pearl pigment composition :

Pearls are fine particles in the form of flakes, measuring a few ten thousandths of a millimeter (µm microns).

Initially made with mica, modern pearls have greatly evolved and are now made of different materials, depending on their type and quality, which gives them more purity and iridescence.

Components : Synthetic mica, Silica, Borosilicate, Aluminum, Metal oxides, Polyester

Sedimentation :

Warning ! during the "curing time" or "gel time" of the resin,

nacres can sediment and fall.

To avoid this phenomenon, it is necessary to ensure a fast hardening of the resin:

several solutions exist :

- choose the most suitable type of resin

- and ensure a sufficient thickness, to create a fast hardening

(for 4000 resin : 3 cm, for WWA resin: 10cm)

The phenomenon of pearl deposition is faster with pearls of the Diamond type or flakes.

Tinting the pearls with Candy epoxy inks :

To increase the glittering effect, the depth effect and the resin brightness, there is a technique that consists not simply using pearl + resin, but also of adding translucent inks for epoxy resin

These inks are compatible with all resins and are highly transparent: the light passes through, bounces off the pearl, and leaves tinted up to the observer's eye. The quality of the colour visual effect is higher than that obtained with an already coloured pearl, because it is a "light colour".

All types of pearls, especially white, diamond, or metallized, can be used.

Pearly pigment for a projected effect :

Our colored powder pearls allow you to create a “projected effect” on bodywork.

These colored pearl pigments can be sprayed dry on the bodywork (background painted and sanded with P500).

This projected pearl effect can then be sealed and fixed with a simple varnish.

We also offer a series of professional quality mother-of-pearl with a very high level of UV and temperature resistance.

These are crystal pearls which have a colorless appearance and which produce a colored appearance and reflections when they are applied on a black background

Do not breathe nacre, work with overalls in a paint booth with extraction

Resistance :

Pearls are highly resistant to temperatures and UVs.

Safety :

S22 : Do not breathe dust. The pearl powders are very fine and volatile, they should not be inhaled. Work with air extraction during the mixing. Once mixed, they are no longer dangerous.

River table from Jeff Mack, Canada. All rights reserved

FAQS :

Question :

I would have liked to know what quantities of mother-of-pearl and pigment it would be necessary to use in order to obtain the river table result illustrated on your page:

Answer :

In all cases, the dosages must be made at the time by gradually adding the mother-of-pearl (spoon by spoon) and the candy coloring (drop by drop) until the desired shade is obtained.

It is of course not possible to go back if too much product has been added, and there is a risk of clouding of the resin layer. It is important to maintain transparency and lightness in the dosage.

The dosage depends greatly on the thickness of the resin.

Pearls : 5 to 20 g/L

Candy coloring : 0.5 to 5g / L

StardustColors is a specialist and leading company in the field of pearl pigments. The Stardust® pearl and flake brand includes nearly 200 references.

These are organic pigments and flakes based on metal or glass not impacted by the European regulation "ECHA Microplastics Annex XV"

Accessories

19 other products in the same category

WE ALSO RECOMMEND YOU

Recently Viewed

- Special Effect Paints

- Chrome Effect

-

Car and motorcycle paint

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

.

.

.

-

MOTO COLOUR CODE

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

.

.

-

CAR COLOUR CODE

- Finish Paints and Topcoats

-

Specialties

-

Accessories and consumables

.

.

- AIRBRUSH PAINT

- COLORCHART