All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

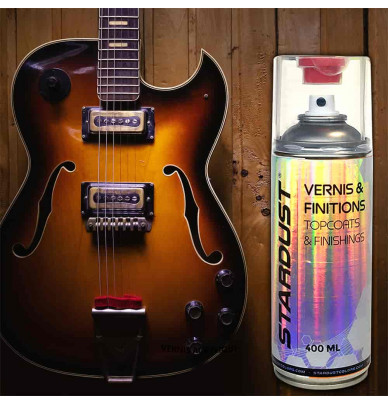

Polyurethane, Nitrocellulose, and Acrylic Guitar Clearcoat

Guitar Clearcoat - 5 Types to Choose From

Acrylic Clearcoat 500ml (Matte or Glossy)

Nitrocellulose Clearcoat 500ml

Polyurethane WetSpeed Kit 875ml

Ceramic Clearcoat Kit 1 Liter

UHS Aerosol Clearcoat 290ml

Products in stock and delivered within 48 hours

The clearcoat of a guitar is a transparent finishing layer that provides protection for the wood or paint against aging, scratches, abrasions, friction, moisture, and dirt.

Clearcoat also serves an aesthetic function on a guitar by enhancing colors, depth, and the texture of the wood. Unlike impregnating hydro resins, clearcoat does not create a wet wood effect on the guitar (lien produit 1010)

Clearcoat can blend with the wood of the guitar's top, soundbox, without interfering with the natural acoustic qualities of the wood. There is no real interference between clearcoat and the produced sound under normal application conditions.

On this page, we present 5 excellent clearcoats for varnishing a guitar, carefully selected from our range of professional clearcoats. These 5 clearcoats can be applied with a brush and preferably with a paint gun. We provide mixing and offer details further down the page.

1 – 100% Water-Based Acrylic Clearcoat, 1K Matte or Glossy

2 – Nitrocellulose Clearcoat, 1K Glossy

3 – Polyurethane WetSpeed Clearcoat, 2K Glossy

4 – Ceramic Clearcoat, 2K Glossy

5 – Bicomponent Aerosol Polyurethane Gloss Clearcoat

At the end of this page, we also present a range of transparent colorants suitable for clearcoat, as well as a type of epoxy resin for creating a glaze on a guitar.

Click here to read our blog article on "How to Varnish a Guitar?"

Only small packaging suitable for guitars is offered on this page.

Which Clearcoat to Choose for a Guitar ?

Each clearcoat has its qualities and some drawbacks, however, it is true that some clearcoats have far more qualities than others..

♫ Our acrylic clearcoats are odorless and water-based. They are pleasant to use, especially indoors. These are professional and innovative formulas, whose resistance, gloss, and drying properties have been notably optimized in recent years. These are one-component clearcoats with "air" drying.

♦ Ready to use / dilutable with a maximum of 10% water

♦ Gloss: +60° / Matte: 20° / Thickness: 2 coats = 50 microns

♦ Advantages: simple, natural, and odorless / Disadvantages: limited gloss and resistance

♫ Our cellulose clearcoat is a solvent-based, single-component glossy clearcoat that dries through evaporation. We offer this clearcoat naturally as it is favored by many audiophiles who have retained the habit. Used by some major guitar brands for much of the twentieth century, it has certain qualities: fast drying, finesse, and the ability to blend with the old layer of cellulose clearcoat. However, its quality is also its weakness, as it does not fully harden, so it can dissolve with a cleaner or certain products. Furthermore, its lack of resistance does not ensure a long lifespan.

♦ Ready to use

♦ Gloss: +75° / Thickness: 2 coats = 40 microns

♦ Advantages: easy to apply, beautiful gloss / Disadvantages: toxicity, limited gloss and resistance

♫ Our polyurethane clearcoat « WET Speed » is a solvent-based high-gloss two-component clearcoat that hardens through polymerization with its hardener (2:1). It comes from the automotive world and has the main feature of very rapid drying or rather hardening (through dry 2h). It is particularly suitable for guitars and forms a layer with a covering, wet, glossy appearance. Its resistance to abrasion and products is excellent, and it ensures good durability for at least 10 years. Polishing is easy.

♦ Mix 100 parts of clearcoat / 50 parts of hardener / 10-15 parts of thinner

♦ Mixture lifespan: 30 min

♦ Gloss: +90° / Thickness: 2 coats = 50 microns

♦ Advantages: high resistance, high coverage, and gloss / Disadvantages: toxicity, mixing required

Kit 500ml Clearcoat Wetspeed + 250ml Hardener HWS + 125ml Thinner V1

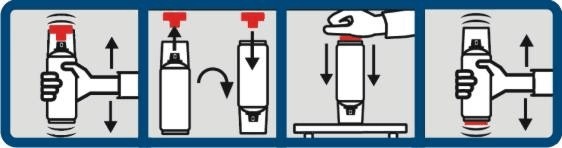

♫ UHS830 Aerosol Clearcoat : The aerosol clearcoat is also a 2-component clearcoat, thanks to this aerosol with 2 compartments. It is a single-use aerosol clearcoat that produces the same level of quality and results as a professionally applied clearcoat with a spray gun. To use it: press the red button under the aerosol, shake well for 30 to 60 seconds, then use the contents of the aerosol within 45 minutes maximum. Apply 2 glossy coats with a 10-minute interval.

♫ Ceramic Clearcoat CERASTAR ST8900X : The CERASTAR ST8900X ceramic clearcoat is a very liquid, two-component, solvent-based clearcoat that hardens through polymerization between the clearcoat and its hardener (1:1). Its specular gloss level exceeds 90°. Very fine and very resistant, it can be applied in 1 or 2 coats. Its dry film is obtained in 45 minutes (Through-drying) and allows for a record hardness of 400* (24h) and 440* (48h) when the best automotive topcoats reach 270* over several days of drying.

♦ Mix: 100 parts of clearcoat / 100 parts of hardener / no dilution

♦ Mixture lifespan : 20/30 min

♦ Gloss : +90° / Thickness : 2 coats = 40 microns

♦ Advantages: high resistance, high coverage, and gloss / Disadvantages: toxicity, mixing required

(*PERSOZ hardness UN EN ISO1522)

Kit 500ml Clearcoat ST8900X + 500ml Hardener H440

Application of Clearcoats on Guitars

Preparing the Surface

If you are working on raw wood (such as cedar, mahogany, spruce, oak, rosewood, maple), the wood should be sanded with P400 sandpaper and then dusted off with compressed air or a brush.

To impregnate the wood, we recommend applying 1 or 2 coats of clearcoat on the first day.

The next day, sand with P500 sandpaper and apply 2 coats of glossy finishing clearcoat.

On electric guitars, typically worked on a painted surface, sanding should be done to create adhesion. This is a superficial sanding with P500 paper.

Before varnishing, the surface must be clean, meaning it should be healthy, dry, degreased, and dust-free.

Application Method for Clearcoat

A guitar clearcoat should be applied in 2 coats.*

When working with a spray gun (1.0 – 1.4mm nozzle) :

One coat corresponds to one back-and-forth pass.

The 2 coats should be separated by sufficient time (the interval).

This allows for the evaporation of part of the solvent or water from the first coat. The interval depends on the ambient temperature, but also on the type of clearcoat: at 20°C, acrylic and polyurethane clearcoats require about 10 minutes, while nitrocellulose clearcoats require 5 minutes.

Generally, a medium first coat (neither too thick nor too thin) is applied, followed by a final, glossy second coat, to allow the clearcoat to level and "tighten".

Ideal application conditions : work between 15 and 25 degrees Celsius, in a dry and dust-free environment.

*Applying more than 2 coats in a single varnishing session increases the thickness but also increases the chances of gloss reduction.

When working with a brush : you can pour a quantity of clearcoat on the guitar and spread it over the surface. Sufficient thickness should be allowed for the clearcoat to self-level.

Colorants for Guitar Clearcoats

A colorant differs from a pigment in its complete transparency and solubility. It allows light to pass through the clearcoat in which it is mixed and "colors the light".

It creates both a color and depth effect, allowing for the creation of dark and transparent effects through the multiplication of layers.

We offer these transparent "Candy" shades in concentrated form, in solvent-based versions for tinting cellulose or solvent-based polyurethane clearcoats, or in H2O versions for tinting acrylic clearcoats.

Generally, the dosage should be between 5 and 7% of the weight of the pure clearcoat, without hardener or dilution.

Correction and Polishing of Guitar Clearcoats

After a sufficient drying or hardening time, a clearcoat can be polished to a shine.

The technique allows for obtaining a "beautiful mirror clearcoat" and can be done on a guitar manually or with a mini polisher, and a series of sheep's wool or foam, and a polishing paste.

All products can be found in the polishing category

Polishing is done either when you want to remove a localized defect in the clearcoat and/or to enhance the gloss of a clearcoat.

We invite you to check out this tutorial for clearcoat polishing and buffing.

Acoustic Properties of Clearcoats

Clearcoats can be more or less flexible or rigid.

Acrylic or cellulose clearcoats are more flexible, while polyurethane or ceramic clearcoats are harder. According to professional luthiers, polyurethane clearcoats give results at least equal in quality to the old cellulose clearcoats, acoustically speaking.

When clearcoat is applied according to the application instructions, with 2 coats, it creates a dry film after evaporation, with a thickness not exceeding 1/20 of a millimeter. When applying 4 to 6 coats, 100 to 150 µm dry, and even with this level of thickness, no interference with wood vibration and sound wave propagation has been reported.