All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

-

Special effect paints

- Chameleon effect paints

- Paint with an opalescent pearlescent sheen

- Prismatic Paints

- Candy Paints

- The fluorescent paints

- Phosphorescent paints

- Fluorescent paints UV

- Crystal Pearlescent Clearcoat

- Marble and crystal paint

- Paints that react to temperature

- Paints that react to light

- Magnetic paint and rust color

- Chrome effects

-

Our paint ranges for bodywork

-

PAINT KIT FOR CAR BODYWORK

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

- Primers for car paints

- Epoxy-polyester paint for wheel rim

- Spraypaint bodywork

- Metallic effect paints for car bodywork

- Tuning paints with effects

- Pearlescent paints for bodywork

- Solvent-based 1K base coats for cars

- 2K paints for cars

- Vintage cars paints

- Rustproof car frame paints

- Car underbodies and pick-up trucks paints

- Car cylinder block paints

- Dashboard paints

- Car brake paints

- Plastic bumper paints

- Car wing mirror paints

-

CAR COLOUR CODE

-

PAINT KIT FOR MOTORCYCLE BODYWORK

-

Motorcycle and scooter paint code - Can or spray paint

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

- Motorcycle tuning paints

- Motorcycle paint primers

- Motorcycle spray paints

- Epoxy paints for motorcycle frames

- Epoxy paints for motorcycle rims

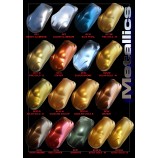

- Metallic motorcycle paints

- Pearly motorcycle paints

- Motorcycle clearcoats

- The paints for plastic of cross country motorcycle

- Jet ski hull paints

- Paints for Quad

-

Motorcycle and scooter paint code - Can or spray paint

- Scooter fairing paints

- Helmet paints

- Auxiliary products

- Bicycle paints - Stardust Bike

- RAL Paint - Pantone Code

-

PAINT KIT FOR CAR BODYWORK

- Finish paints and topcoats

-

Artistic and custom specialties

- EPOXY RESINS

- Gilding with a gold leaf

- Pinstriping paint and brushes

- Hydrographic Film

- Covering car and motorcycle

- Pearls and Flakes bodywork

- Painting over the body

- Paint for fishing decoys

- Paints for guitars

- HIKARI : paints for models and miniatures

- Acrylic 3D Printing Paint – Primers, Colors, and Clearcoat

-

Bodywork accessories and consumables

- HVLP Spray Guns for car and motorcycle paints

- Our ranges of airbrushes

- Compressed air connections

- BODYWORK ACCESSORIES

- Abrasives for bodywork

- Buffing and polishing of bodywork

- Protective Equipment for painters

- POSTERS

- Paint air filters

- sample supports for paint tests

- Infrared and ultraviolet drying lamps for paint

- Bodywork adhesives and paint

- Air compressors for painting

- Paints for airbrush

Black Chrome - Special metallic effect paint

New product

The Black Chrome effect

is a special paint effect sometimes seen on some rims, and difficult to replicate.

1-component product to apply using a spray gun

Delivery within 24hrs

The Black Chrome paint is a metallic effect more than a mirror-like effect chrome paint. Its ultra-fine pigmentation gives it an appearance close to the black chrome effect.

Usually carried out through vacuum metallization techniques, the Black Chrome is proposed in paint format: this very special paint, produced only by StardustColors, offers a dark metal aspect, midway between mercury and anthracite.

The Black Chrome paint can reproduce this effect using a body spray gun, without the requirement for expensive equipment.

The Black Chrome is made from special resin and ultra fine pure metal powder, without any dye.

1-component product (new 2020 version)

Our offers

250ml

500ml

1 L

2 L

1L of mixed product = 5m²

High-yielding product, as it is applied in 2-3 fine passes

The product has a viscosity close to that of water, therefore it’s important to spray very fine passes.

Its evaporating speed is very fast, and there must be an interval of one minute between each coat.

Allow the part to rest, and the mirror-like effect will increase gradually as the product evaporates and dries in the next half hour.

After 10 minutes, the Black Chrome is dry.

Use:

equipment, bodywork, auto or moto rims, bottles, cell phone, decoration

Summary of the Black Chrome application steps:

Apply with a spray gun only

Air pressure: 2.00 - 2.5 bars / Nozzle: =<1.4mm

Shake well before use

Apply a couple of very fine coats over a gloss hard background (2K lacquer or 2K topcoat dry for at least 48hrs previously).

Application on glossy black background*, perfectly dry and hard:

Any topcoated base, or any bodywork or epoxy 2K paint can be used.

The product can even be applied to an already hardened glossy finish (e.g. rim) as long as this surface has been properly cleaned and degreased.

The background must be unsanded and have a very high gloss.

Black Chrome paint adhesion on all type of substrates:

The paint adheres strongly and directly without sanding to the glossy background.

Adhesion is entirely determined by the cleanliness of the bottom.

Drying

Activated by heat and humidity from the air, Black Chrome evaporates quickly.

It can be topcoated after 24 or 48 hours.

Topcoat application

All types of bodywork clear coats can be used: they promote better gloss and resistance to abrasion. Topcoat application must be done very carefully by respecting the special technic of fixing/sticking before wetting:

Apply 4 super dry coats with 2min between each coats, and then apply the clearcoat normally with 2 wet coats. this prevents any loss of mirror effect

the application of 4 micro layers allows the surface to be fixed without wetting or soaking it, which would cause a modification of the mirror effect layer and the position of the mirror effect pigments which must remain horizontal: for this we move the gun 30 to 40 cm away, and we make very rapid passages, with an absolutely minimal flow.

>>> The varnishing of the Black Chrome paint must be done with a special technique also used for the classic chrome paint. To optimize the varnishing and the preservation of the chrome effect, it is recommended to wait 48 hours, or to bake the Black Chrome paint "

How to get the best results

The quality of the chrome effect essentially depends on the hardness and shine of the undercoat (the varnish) so we advise you to use the following products:

- one-component black base

- the base / varnish for chrome (ST8900x ceramic)

Safety:

Danger! Hazardous flammable product. User must be familiar with the safety instructions and observe them. This product is for professional use only.

21 other products in the same category

WE ALSO RECOMMEND YOU

Recently Viewed

- Special Effect Paints

- Chrome Effect

-

Car and motorcycle paint

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

.

.

.

-

MOTO COLOUR CODE

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

.

.

-

CAR COLOUR CODE

- Finish Paints and Topcoats

-

Specialties

-

Accessories and consumables

.

.

- AIRBRUSH PAINT

- COLORCHART