All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

-

Special effect paints

- Chameleon effect paints

- Paint with an opalescent pearlescent sheen

- Prismatic Paints

- Candy Paints

- The fluorescent paints

- Phosphorescent paints

- Fluorescent paints UV

- Crystal Pearlescent Clearcoat

- Marble and crystal paint

- Paints that react to temperature

- Paints that react to light

- Magnetic paint and rust color

- Chrome effects

-

Our paint ranges for bodywork

-

PAINT KIT FOR CAR BODYWORK

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

- Primers for car paints

- Epoxy-polyester paint for wheel rim

- Spraypaint bodywork

- Metallic effect paints for car bodywork

- Tuning paints with effects

- Pearlescent paints for bodywork

- Solvent-based 1K base coats for cars

- 2K paints for cars

- Vintage cars paints

- Rustproof car frame paints

- Car underbodies and pick-up trucks paints

- Car cylinder block paints

- Dashboard paints

- Car brake paints

- Plastic bumper paints

- Car wing mirror paints

-

CAR COLOUR CODE

-

PAINT KIT FOR MOTORCYCLE BODYWORK

-

Motorcycle and scooter paint code - Can or spray paint

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

- Motorcycle tuning paints

- Motorcycle paint primers

- Motorcycle spray paints

- Epoxy paints for motorcycle frames

- Epoxy paints for motorcycle rims

- Metallic motorcycle paints

- Pearly motorcycle paints

- Motorcycle clearcoats

- The paints for plastic of cross country motorcycle

- Jet ski hull paints

- Paints for Quad

-

Motorcycle and scooter paint code - Can or spray paint

- Scooter fairing paints

- Helmet paints

- Auxiliary products

- Bicycle paints - Stardust Bike

- RAL Paint - Pantone Code

-

PAINT KIT FOR CAR BODYWORK

- Finish paints and topcoats

-

Artistic and custom specialties

- EPOXY RESINS

- Gilding with a gold leaf

- Pinstriping paint and brushes

- Hydrographic Film

- Covering car and motorcycle

- Pearls and Flakes bodywork

- Painting over the body

- Paint for fishing decoys

- Paints for guitars

- HIKARI : paints for models and miniatures

- Acrylic 3D Printing Paint – Primers, Colors, and Clearcoat

-

Bodywork accessories and consumables

- HVLP Spray Guns for car and motorcycle paints

- Our ranges of airbrushes

- Compressed air connections

- BODYWORK ACCESSORIES

- Abrasives for bodywork

- Buffing and polishing of bodywork

- Protective Equipment for painters

- POSTERS

- Paint air filters

- sample supports for paint tests

- Infrared and ultraviolet drying lamps for paint

- Bodywork adhesives and paint

- Air compressors for painting

- Paints for airbrush

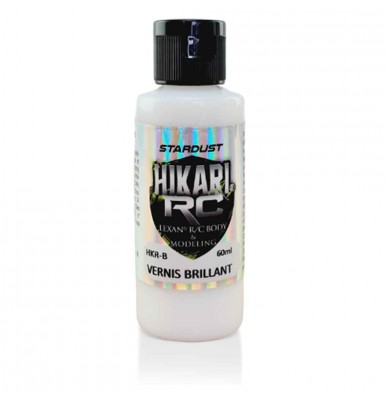

Special Lexan clearcoat and RC models - acrylic gloss or matte

New product

Clear Lexan clearcoat

2 versions to choose from : gloss or matte

60ml / 250ml / 1L / 5L

In stock, express delivery anywhere in the world

HKR Gloss or Matte Clearcoat is used specifically for radio modelling on Lexan bodies.

It is an innovative and unique clearcoat with a water-based aliphatic acrylic polyurethane formula that is odorless and contains less than 3% solvents.

This HKR Lexan clearcoat shows exceptional adhesion performance on Lexan. It also adheres to a variety of soft substrates and metals (iron and aluminum).

It is also a particularly tough, impact resistant clearcoat with good flexibility.

It is an excellent carrier clearcoat for mixing colors, pearls or flakes.

Finally, HKR clearcoat provides excellent color protection against UV rays.

Use :

Its fluid texture allows for use with a spray gun or airbrush

It can be applied in 1 or 2 coats on or under the bodies of radio-controlled vehicles made of Lexan.

It is mainly applied on RC bodies to restore shine and remove micro-scratches

It is used by RC painters and decorators to create a matte finish on glossy original bodies.

HKR clearcoat is also perfect for incorporating any kind of pearl pigments or flakes or hydro candy concentrate, and in this case it is applied as a first coat, under the bodywork

HKR clearcoat is not suitable for permanent immersion. For models immersed in water, we recommend our 2-component clearcoats.

Mixing and adjusting

Airbrush nozzle >=0,3mm

Gun nozzle 0,8-1,4mm

Pressure : 2.5 bar

Dilution : possible at 5-10% with distilled water or Hikari RC thinner. Do not exceed this level of dilution, as it may affect the adhesion and lengthen the drying time.

Application

On a sanded or unsanded, degreased and dry surface

Apply one to two coats, 0.3 to 0.5 mm thick when wet

Allow 10-15 minutes drying time at 20°C before applying the second coat.

The maximum recoat time is 2 days without sanding, therefore, if in doubt, extend the drying time between coats

Avoid the application of too thin coats : Risk of loss of gloss and loss of adhesion.

Avoid applying too thick coats : Risk of milky effect and dripping.

Drying

Do not bake or oven dry, as this may result in reduced adhesion

It is possible to accelerate the drying process with a moderate source of hot air

Do not sand for at least 6 hours

HKR clearcoat can be polished after 48 hours

On difficult substrates, wait 48 hours to obtain maximum adhesion properties.

Adhesive masking (tapes)

Adhesive application possible from 1 hour

Without sanding until 48h

After 48h, the HKR clearcoat has hardened, and it is advisable to make a light sanding with P600 before painting.

Glossiness :

HKR glossy : 75-85

HKR matte: 4°.

HKR gloss and matte clearcoats are miscible and allow to obtain different levels of gloss, after mixing.

18 other products in the same category

WE ALSO RECOMMEND YOU

Recently Viewed

- Special Effect Paints

- Chrome Effect

-

Car and motorcycle paint

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

.

.

.

-

MOTO COLOUR CODE

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

.

.

-

CAR COLOUR CODE

- Finish Paints and Topcoats

-

Specialties

-

Accessories and consumables

.

.

- AIRBRUSH PAINT

- COLORCHART