All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

-

Special effect paints

- Chameleon effect paints

- Paint with an opalescent pearlescent sheen

- Prismatic Paints

- Candy Paints

- The fluorescent paints

- Phosphorescent paints

- Fluorescent paints UV

- Crystal Pearlescent Clearcoat

- Marble and crystal paint

- Paints that react to temperature

- Paints that react to light

- Magnetic paint and rust color

- Chrome effects

-

Our paint ranges for bodywork

-

PAINT KIT FOR CAR BODYWORK

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

- Primers for car paints

- Epoxy-polyester paint for wheel rim

- Spraypaint bodywork

- Metallic effect paints for car bodywork

- Tuning paints with effects

- Pearlescent paints for bodywork

- Solvent-based 1K base coats for cars

- 2K paints for cars

- Vintage cars paints

- Rustproof car frame paints

- Car underbodies and pick-up trucks paints

- Car cylinder block paints

- Dashboard paints

- Car brake paints

- Plastic bumper paints

- Car wing mirror paints

-

CAR COLOUR CODE

-

PAINT KIT FOR MOTORCYCLE BODYWORK

-

Motorcycle and scooter paint code - Can or spray paint

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

- Motorcycle tuning paints

- Motorcycle paint primers

- Motorcycle spray paints

- Epoxy paints for motorcycle frames

- Epoxy paints for motorcycle rims

- Metallic motorcycle paints

- Pearly motorcycle paints

- Motorcycle clearcoats

- The paints for plastic of cross country motorcycle

- Jet ski hull paints

- Paints for Quad

-

Motorcycle and scooter paint code - Can or spray paint

- Scooter fairing paints

- Helmet paints

- Auxiliary products

- Bicycle paints - Stardust Bike

- RAL Paint - Pantone Code

-

PAINT KIT FOR CAR BODYWORK

- Finish paints and topcoats

-

Artistic and custom specialties

- EPOXY RESINS

- Gilding with a gold leaf

- Pinstriping paint and brushes

- Hydrographic Film

- Covering car and motorcycle

- Pearls and Flakes bodywork

- Painting over the body

- Paint for fishing decoys

- Paints for guitars

- HIKARI : paints for models and miniatures

- Acrylic 3D Printing Paint – Primers, Colors, and Clearcoat

-

Bodywork accessories and consumables

- HVLP Spray Guns for car and motorcycle paints

- Our ranges of airbrushes

- Compressed air connections

- BODYWORK ACCESSORIES

- Abrasives for bodywork

- Buffing and polishing of bodywork

- Protective Equipment for painters

- POSTERS

- Paint air filters

- sample supports for paint tests

- Infrared and ultraviolet drying lamps for paint

- Bodywork adhesives and paint

- Air compressors for painting

- Paints for airbrush

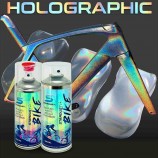

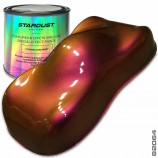

Spectrum Covalent 2X - Prismatic Paint

New product

Spectrum Covalent - Professional version

Liquid and bi-component holographic paint for glass adhesion and fast curing for fast varnishing

Dangerous product reserved for professionals

Hangs all support - varnish easily

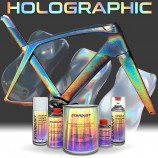

Spectrum Covalent - Iridescent prismatic effect Paint

The Spectrum Covalent is the world’s finest “holographic rainbow” effect paint, with a particle size of 10 or 12µm!

It acts like a prism and creates iridescent rainbow effects on the surface of the painted object, depending on the angle at which it’s viewed.

Liquid product easy to paint and to clear coat.

1K Ready for use

Superior adhesion on all substrates!

StardustColors has developed this unique special effect product for the paint and coating fields:

Spectrum Covalent is a new special version of the slightly less intense Spectrum holographic paint for glass. but easier to varnish, and does not pose problems of adhesion on glossy backgrounds: it has the power to hang directly on various types of even the most difficult surfaces such as chrome or glass:

- All ferrous and non-ferrous metals

- Plastics

- Lacquers, topcoat

- Glass

- Other

Important! The Spectrum Covalent works on glossy surfaces only. It is inoperative on matte surfaces. No sanding should be performed. If your surface is not glossy, we recommend to apply an adhesion polyurethane topcoat on all substrates that will provide a smooth and glossy background.

To ensure adhesion, it’s very important to have a well cleaned, degreased and dried surface.

Other exceptional properties:

In addition to direct application over the substrate (without primer), it also provides the following:

- Evaporates within 60 to 180 seconds forming a resistant film of a few microns thick.

- Semi-transparent, does not change the background colour*.

- Fully resistant to UVs or high temperatures.

- Can be kept without topcoat, or can be easily clearcoated to increase gloss and durability

> Access the data sheet by scrolling to the bottom of the page.

All background colours:

Being semi transparent, it can be applied over any background colours without changing the hue, provided you do not apply more than 3 or 4 thin passes.

> Note that the darker the background, the more intense and visible the holographic effect is. On a white or light background, it provides an opalescent effect like a pearl.

Light refraction properties: the dry Spectrum film (<3-5µm) returns an iridescent reflection showing all the colours of the rainbow (by defragmentation of the light)

The Spectrum coat remains invisible* in the absence of direct light: for example, when the Spectrum Covalent is applied over a glass surface, it will keep the near perfect transparency of the glass.

*Over black or dark backgrounds, the effect may be visible in the form of a greyish veil.

In all cases, the iridescent rainbow effect is not visible out of direct light.

Use and possibilities:

The "Spectrum Covalent" is specially designed for glass

It offers amazing possibilities, in terms of innovative and attractive visual effects in the industrial fields of object finishes: mobile phones, accessories, glass, bottling and crystal glass, pots and pans, facades, bodywork, kitchens and furniture

Industrial application with easy application through spraying.

What is adhesion via covalent bonding*:

it’s the connection at the atomic level, when the electrons from atoms on the surface of the material (glass, metal, plastic, etc.) and those of the paint are exchanged. This chemical bond produces an extreme chemical bond, without using primer or additives.

Application and yield:

Spray very fine coats directly on the non sanded surface.

The substrate must be smooth and glossy. Due to the fineness of the Spectrum Covalent film, the effect is not visible on matte surfaces

> A matte base is not suitable as a background. A topcoat or a polyurethane lacquer should be used as a background.

Ready to use product yield: 1 L = 8-10m²/pass

Yield:

The product is concentrated and a small amount should be applied.

Apply 1-3 passes

USE: DATA SHEET

Substrate:

MUST BE A GLOSS, HARD, HEALTHY AND DRY SUBSTRATE.

EXCELLENT ADHESION ON PLASTICS, METALS, GLASS, TOPCOAT AND RESIN, WITHOUT SANDING.

DO NOT SAND THE SUBSTRATE.

Preparation:

RFU

Application/settings: SPRAYING WITH SPRAY GUN

INTERVALS BETWEEN COATS: 10 TO 20 SECONDS AT 20°C

Thickness: DRY: 2 TO 5µm

Drying:

DRYING IS TRIGGERED BY EVAPORATION, THE AIR AND ITS HUMIDITY

THE DRYING CAN BE SPEEDED UP BY TEMPERATURE

DRY TO THE TOUCH: 1 MIN

THROUGH-DRY:

3 DAYS AT AMBIENT TEMPERATURE

IF BAKING: DESOLVATION BEFOREHAND: 10MIN AT 20-40°C

1h BAKING/180°C - 5min/250°C

Covering:

RECOMMENDED INTERVAL BETWEEN EACH TOPCOAT PASS: 10-60MIN

ALL TYPES OF GLOSS TOPCOATS ARE SUITABLE

Shelf life:

STORAGE: 1 MONTH IN ORIGINAL PACKAGING, STORED BETWEEN 10°C AND 20°C

Topcoat application

A topcoat is necessary because the product matifies as it dries. The effect will be visible only after varnishing

The Spectrum Covalent can be covered with all types of topcoats after 5min and up to 45min, without any loss of iridescent effect (rather, the holographic effect is increased tenfold and magnified by a gloss topcoat).

Product for use by professionals only.

Special varnishing technique for Spectrum type paints.

the Spectrum may lose its prismatic effect when covered with varnish:

liquids (water-based or solvent-based varnishes) can soak the prismatic surface and modify the position of the micro-pigments on the surface.

In order to avoid the loss of the prismatic effect, it is necessary to "fix" the paint with the following technique, then varnish normally:

Apply 4 "extra dry" coats of varnish, 2 minutes apart, then varnish normally with 2 gloss coats

To keep the transparency, it is advisable not to exceed 2 or 3 thin coats.

12 other products in the same category

WE ALSO RECOMMEND YOU

Recently Viewed

- Special Effect Paints

- Chrome Effect

-

Car and motorcycle paint

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

.

.

.

-

MOTO COLOUR CODE

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

.

.

-

CAR COLOUR CODE

- Finish Paints and Topcoats

-

Specialties

-

Accessories and consumables

.

.

- AIRBRUSH PAINT

- COLORCHART