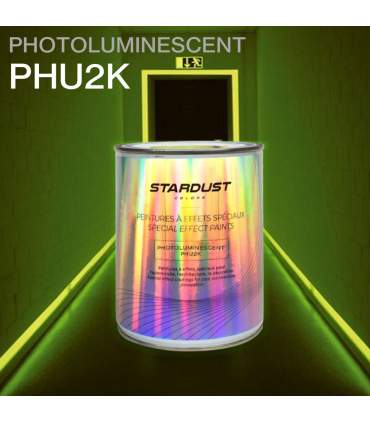

Two-component photoluminescent polyurethane varnish

Several versions to select from the packaging menu

(flexible versions are special versions)

POLYURETHANE PHOSPHORESCENT PAINT

This product can be qualified as a topcoat as it's glossy, transparent at 80%, and resistant: Even after 5 coats, you still can see perfectly the pattern or the background colour underneath.

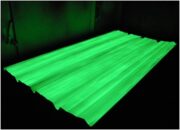

By a natural and non harmful phenomenom, the phosphorescent effects topcoats produce light, after having charged with natural or artificial light. They emit light up to 10h without any difficulty, it depends mainly of the colour and of the thickness of the coat. It takes only a few seconds to some minutes of charge.

This product is very resistant and specially designed for outdoors:

It's water and oil proof, resists perfectly to acids, bad weather conditions and to heat up to 180°C and has a lifetime of 20 years. It adheres very well on many types of supports such as wood, concrete, metals, stones,... 3 to 4 coats allow a very good luminescence, after 30 to 60min of charge, and it will glow during 12h in complete darkness.

CHARACTERISTICS and ASPECT:This product is transparent and colourless (very light greenish aspect). When the paint is dry, it forms a glossy film, as resistant and waterproof than an automotive bodywork clear coat.

USE: The product is ideal for outdoors.The paint is also suitable for indoors if the rooms are well ventilated during the drying.

Two-component system: You mix the basecoat with the hardener and the whole must be used within half an hour.

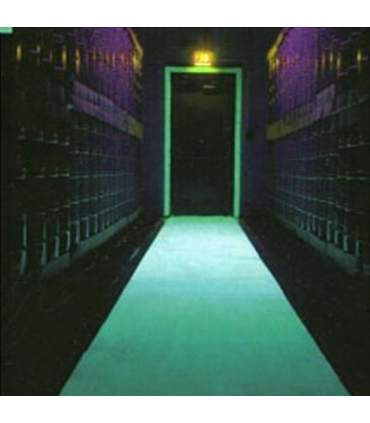

DESTINATION : Bodywork, signals on construction engines, floors and walls, equipments. Always over a white background.

PRECAUTIONS : Products for professional use. In all cases work

in well ventilated places or outdoors, wear a special respirator mask against VOC and protective gloves.

Type of product : Solvent based polyurethane topcoat. VOC: < 420 G/L .

Offers:Select in the scolling menu above

250mL + 100ml Hardener + 80g pigments = 350ml kit

1L + 330ml Hardener + 330g pigments = 1.33L kit

3L + 1L Hardener + 1kg pigments = kit 4L

Kit 1.2L Flexible varnish

Kit 6L Flexible varnish

Theorical coverage: 2 sqm / L

Mixing ratios :

Mixture by weight, in order:

• 100 base 830

• 33 parts of powder

• 33 parts of hardener H432

Mix thoroughly before use and mix regularly during application to avoid sedimentation.

Mix only the necessary dose and sticky usable for 30 minutes (Pot Life)

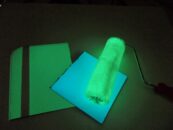

Application: Brush, roller or spray gun. By preference over a WHITE paint or primer, or over a rough background of light colour. >Use our white primer for Concrete, or our white primer for Metals (see our section Primers)

Number of coats: 3-5 passes with an interval of 2-5min between each. Pot life : 25min

Drying time: At 20°C : Touch dry: 1h – Service : 24-48h

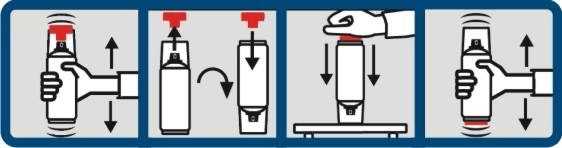

How to use 2K spraycan :

The PHCEL2K version is a flexible phosphorescent varnish. This varnish suits on covers and leathers for example.

Read our blog, to know more about photoluminescence

Flexible Formula

The PHCEL2K version is a flexible phosphorescent varnish. This varnish is suitable for tarpaulins and leather for example. It also has excellent adhesion power (installation without primer) on materials such as plastics or metals.

The mixture is done by weight: 1230g of base for 108g of hardener or

1000g of base for 88g of hardener

PHCEL2K Offers: Select from the drop-down menu above

- Kit 1.35L Flexible Varnish = 1L Base + 150ml Hardener H410 + 200g Phosphorescent Pigments

- Kit 6.75L Flexible Varnish = 5L Base + 750ml Hardener H410 + 1Kg Phosphorescent Pigments

PHU2K varnish classified as fire-resistant

Photoluminescent varnish tested and approved according to smoke standard EN 45545 HL2